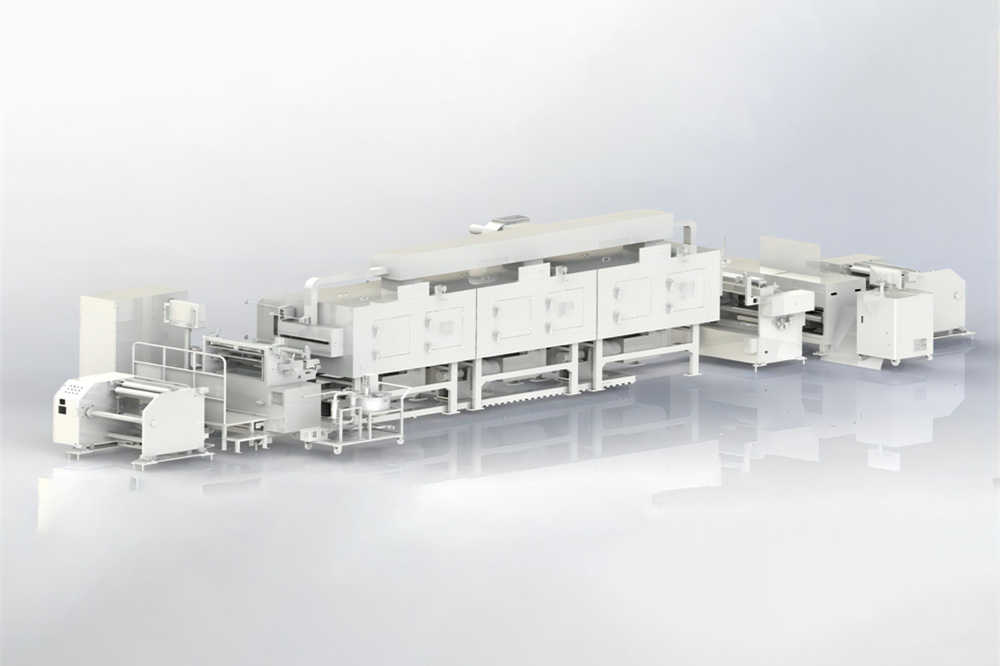

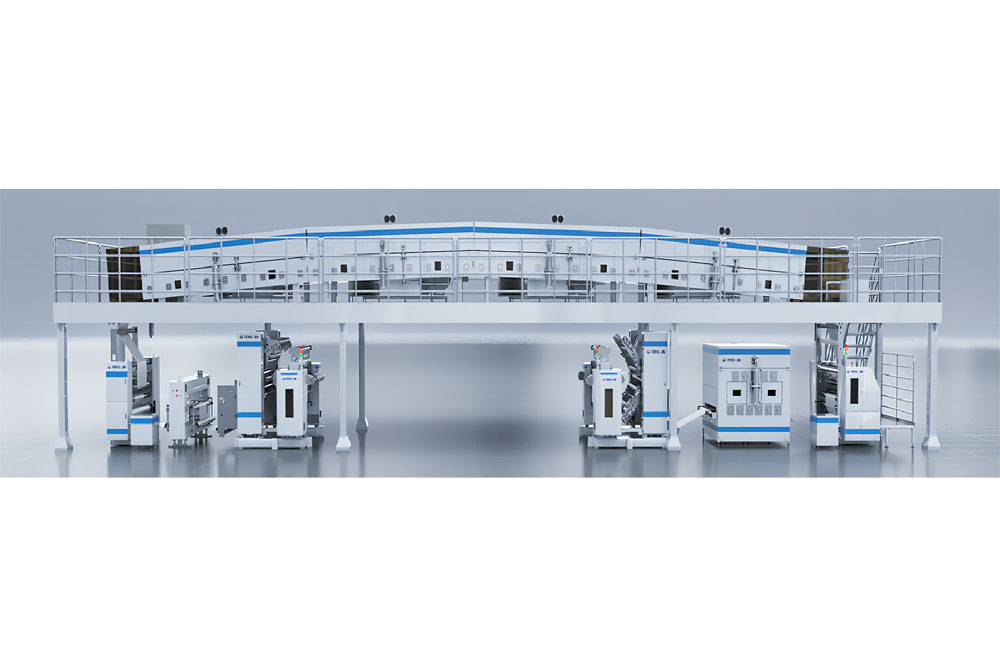

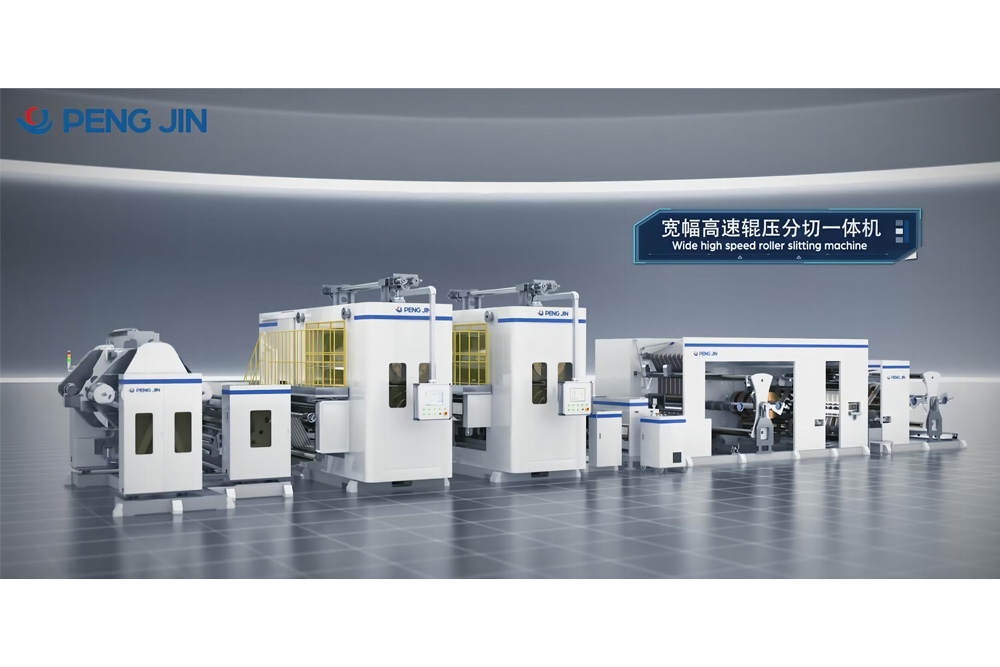

Akwa mkpuchi extrusion dị elu maka mkpuchi dị elu

Uru akụrụngwa

Ihe mkpuchi mkpuchi

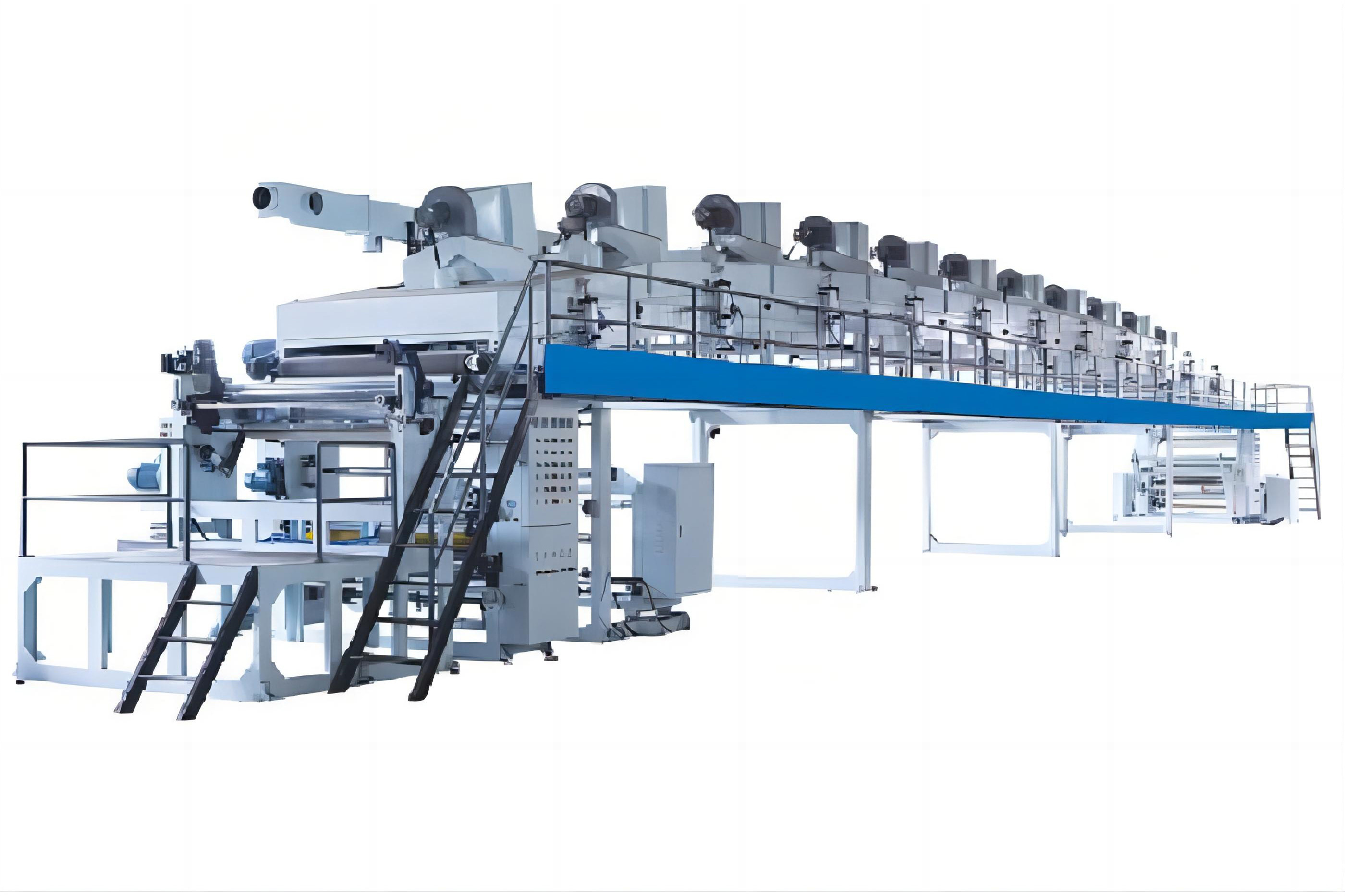

1. Nabata ụzọ gas okpukpu abụọ inflatable n'ibu chuck, iji zere nsogbu nke omenala otu gas ụzọ chuck retracts mgbe ọ na-ebili, na iji zere eriri igwe na-ada.

2. A na-anakwere usoro ogwe aka nke abụọ na-eduzi iji dochie ọnọdụ nduzi nke telescopic shaft, nke nwere uru nke iguzogide iyi, ikike ibu siri ike na ntụkwasị obi dị elu.

3. Ugboro abụọ mgbapụta yiri nri adopts A \ B ịghasa mgbapụta elu na trough contraposition imewe, nke nwere ike melite nkwụsi ike nke mkpuchi nsogbu ma si otú melite agbanwe agbanwe nke ebe njupụta.

4. Tinye isi igwe B-ihu n'elu ikpo okwu nke onwe ya na ala nke abụọ ma wepụ ya na ikpo okwu ígwè na ọdụ, si otú a na-ezere mmetụta nke vibration nke ọdụdụ ọdụ na nkpuchi ziri ezi; Kagbuo usoro ịrị elu iji wepụ ihe ize ndụ nke ịrị elu na wrinkling.

5. Ọkachamara mmiri nyocha na imewe, nnwere onwe nloghachi ikuku cavity imewe, dozie nsogbu nke enweghị ihicha ihicha, curling na overdrying na abụọ na n'etiti ebe okporo osisi ibe.

6. Oven mmiri ịme anwansị, pụrụ iche haziri mgbali enyemaka nozzle Ọdịdị + multistage mgbali equalizing oghere, mpụta ifufe ọsọ fluctuation nke otu nozulu bụ ≤ ± 2% (tụtara), nke mma ihicha agbanwe agbanwe na-ebelata ihe ize ndụ nke okporo osisi ibe deviation na. oven.

7. Ụlọ ọrụ ahụ eguzobewo 1600-obosara elu-ọsọ niile-infrared ultra-high-precision extrusion mkpuchi igwe bụ dakọtara na 4um ọla kọpa foil na 6um aluminum foil, full-arch oven imewe, ịnya ụgbọ ala magnetik wheel mbanye, mmezi-free, nkwụsi ike dị elu, mkpuchi ngwa ngwa na-enweghị curling, cracking, wrinkling na nsogbu ndị ọzọ.

FAQS

1. Q: Kedu ka esi emeso ọdịda igwe nke igwe mkpuchi?

A: Ụdị ọdịda dị iche iche ga-eme na usoro nke igwe mkpuchi extrusion, dịka nkwụsị igwe, nkwụsị mmanụ, mmebi na ihe ndị ọzọ. Ihe ngwọta bụ ịlele ma akụkụ igwe ahụ emebiwo ma ọ bụ na-efu, na-edebe igwe ahụ ọcha na akọrọ, na-enyocha mgbe niile ma akụkụ igwe ahụ ọ dị mma, ma dozie ọnọdụ igwe na-agba ọsọ n'oge.

2. Q: Kedu ka esi eme ihe na-adịghị mma nke mkpuchi extrusion?

A: Mgbe ịdị arọ nke mkpuchi extrusion dị njọ, ọ nwere ike kpatara ya site na ihe ndị a: 1. Njirimara rheological nke ihe mkpuchi na-ejighị n'aka; 2. Ngwá ọrụ akụrụngwa: Ngwá ọrụ mkpuchi mkpuchi nwere ike inwe mmejọ na-arụ ọrụ, dị ka ọrụ na-adịghị mma nke extruder na ngọngọ nke isi mkpuchi. 3. Ọrụ na-ezighị ezi: Ọrụ na-ezighị ezi nke ndị na-arụ ọrụ n'oge mkpuchi extrusion, dị ka ngwa ngwa mkpuchi ngwa ngwa ma ọ bụ ngwa ngwa na anya na-ezighị ezi n'etiti isi mkpuchi na mkpụrụ, nwere ike iduga n'ịdị arọ mkpuchi extrusion na-adịghị mma.

3. Ajụjụ: Gịnị bụ ụzọ mkpuchi mkpuchi maka batrị lithium ion?

A: Kwesịrị ekwesị maka batrị lithium bụ ihe abụọ a: 1. mkpuchi mkpuchi, nke a makwaara dị ka mkpuchi mpịakọta; Mkpuchi extrusion, nke a makwaara dị ka spraying.

4. Ajụjụ: Gịnị bụ mkpuchi mpempe osisi?

A: Igwe mkpuchi mpempe akwụkwọ bụ igwe mkpuchi eji eme ihe n'ọhịa nke mkpuchi slurry maka mkpanaka dị mma na nke na-adịghị mma nke batrị lithium. Na n'ihu-ọgwụgwụ usoro nke lithium batrị mmepụta, na osisi ibe bụ ihe dị mkpa n'ichepụta njikọ, na uniformity nke slurry mkpuchi n'elu nke isi metal ugbu a na-anakọta foil nke nti na-adịghị mma osisi iberibe ozugbo emetụta nkwụsi ike na nchekwa nke. batrị lithium arụ ọrụ. Ya mere, igwe mkpuchi mpempe akwụkwọ bụ otu n'ime ihe ndị bụ isi na akụrụngwa mmepụta batrị lithium, ma e jiri ya tụnyere igwe mkpuchi ndị ọzọ, ụlọ ọrụ ahụ nwere ihe mgbochi teknụzụ dị elu.

5. Q: Kedu otu esi echekwa igwe mkpuchi batrị lithium?

A: 1. Lelee skru nke akụkụ niile nke igwe mkpuchi mkpuchi mkpuchi mkpuchi mgbe niile ka ịzere ịdị nro. 2. Lezienụ anya na mmiri na-adịghị, mmiri na-ekpuchi mmiri, mgbochi corrosion na oke nke akụkụ eletrik nke igwe mkpuchi. Ekwesịrị idobe ime igbe ọkụ eletrik na ọnụ ọnụ ka ọ dị ọcha iji gbochie ọdịda eletrik. 3. Mgbe emechiri, akụkụ mita kwesịrị ihicha n'oge iji hụ na a na-ehichapụ ihe tray na turntable na mgbanwe ọ bụla iji gbochie ha imebi. Na-ehicha uzuzu mgbe niile na kabinet eletrik iji gbochie kọntaktị adịghị mma na ọdịda ndị ọzọ, na ihe ndị ọzọ.

uwe mkpuchi

uwe mkpuchi Akwa mkpuchi extrusion dị elu maka mkpuchi dị elu

Akwa mkpuchi extrusion dị elu maka mkpuchi dị elu Akwa mkpuchi dị elu maka mkpuchi dị nro

Akwa mkpuchi dị elu maka mkpuchi dị nro The abụọ ndu ogwe aka Ọdịdị Gravure mkpuchi

The abụọ ndu ogwe aka Ọdịdị Gravure mkpuchi The abụọ ndu ogwe aka Ọdịdị Gravure mkpuchi

The abụọ ndu ogwe aka Ọdịdị Gravure mkpuchi Mkpuchi emelitere: Ihe mkpuchi Micro-Concave dị elu

Mkpuchi emelitere: Ihe mkpuchi Micro-Concave dị elu Akọrọ Electrode Diaphragm Kalenda

Akọrọ Electrode Diaphragm Kalenda Ngwa Hunan Desai NMP Distillation

Ngwa Hunan Desai NMP Distillation Ngwa Shaoxing Fudi NMP Distillation

Ngwa Shaoxing Fudi NMP Distillation NMP distillation akụrụngwa na Ningguo oge

NMP distillation akụrụngwa na Ningguo oge Guangxi Fudi (Qingxiu) NMP mgbake Sistemụ

Guangxi Fudi (Qingxiu) NMP mgbake Sistemụ Ngwa NMP mgbake na Desai, Hunan Province

Ngwa NMP mgbake na Desai, Hunan Province Sistemụ mgbake Xiangyang Foday NMP

Sistemụ mgbake Xiangyang Foday NMP Shangrao SVOLT NMP mgbake Sistemụ

Shangrao SVOLT NMP mgbake Sistemụ Yongning FinDreams Batrị NMP mgbake Sistemụ

Yongning FinDreams Batrị NMP mgbake Sistemụ ASEAN Fodi (Wuming) Sistemụ eji emegharị akụrụngwa NMP

ASEAN Fodi (Wuming) Sistemụ eji emegharị akụrụngwa NMP Sistemụ eji emegharị ihe na Guangzhou Rongjie NMP

Sistemụ eji emegharị ihe na Guangzhou Rongjie NMP

WhatsApp

WhatsApp

Facebook

Facebook

Instagram

Instagram