01

ABOUT US

About Us

Dongguan Pengjin Machinery Technology Co., Ltd.

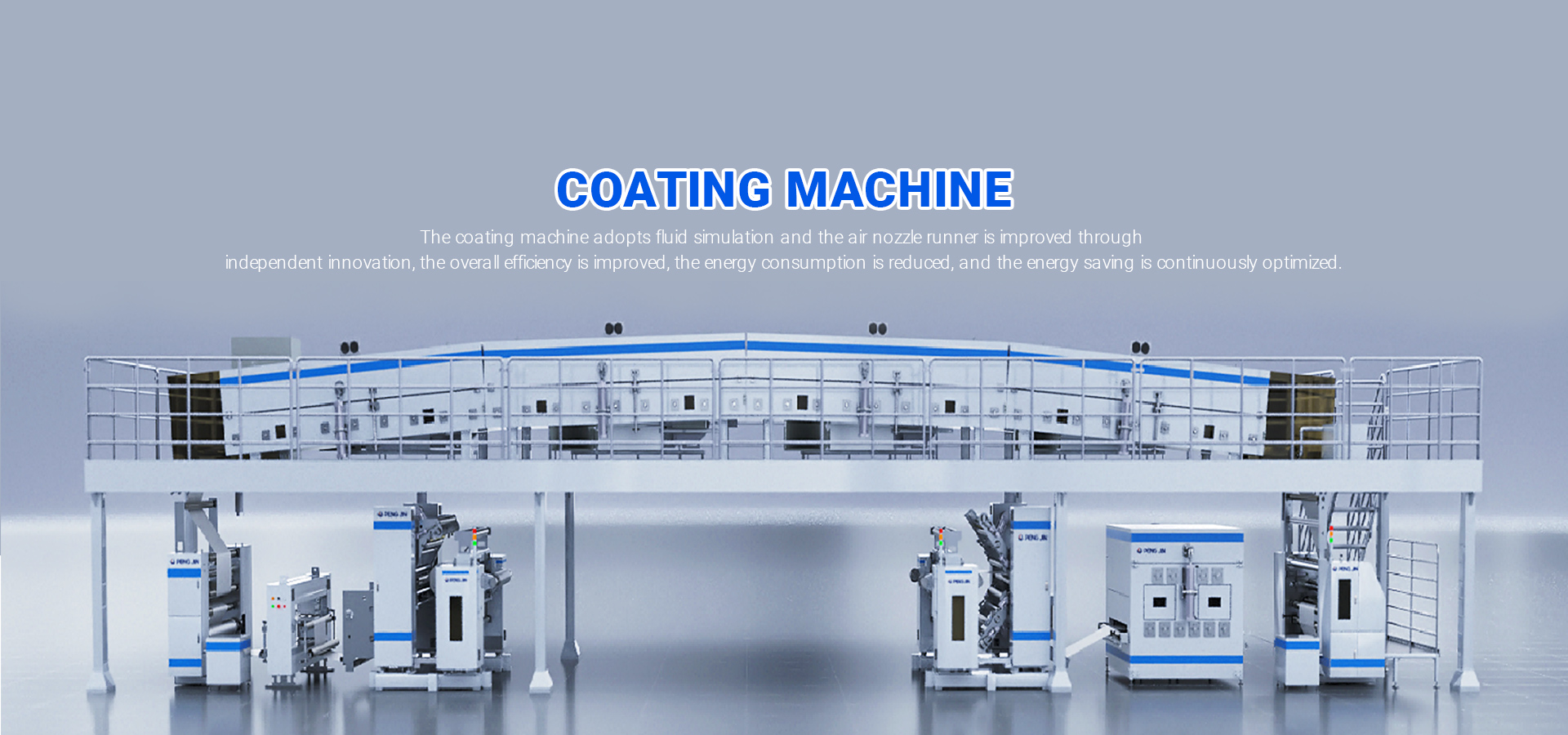

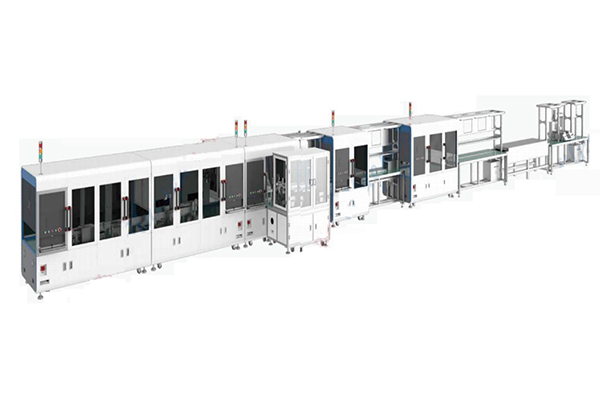

Dongguan Pengjin Machinery Technology Co., Ltd. (Referred to as "Pengjin Technology") is a national high-tech enterprise specializing in professional equipment solutions for the new energy recycling economy. Our primary offerings include NMP recycling equipment, NMP distillation equipment, coating machines, and more.

Committed to innovation, Pengjin Technology holds 13 invention patents and over 50 utility model patents. Our team of nearly 1,000 employees, with around 20% dedicated to research and development, ensures continuous technological advancement.

Read More

13

+

Invention Patent

50

+

Utility Model

1000

+

Company staff and R&D team

10

+

Incorporation

Resource recovery and recycling

Resource recovery and recycling

Supply

Energy saving and emission reduction

28

Green materials and processes

38

Continuous innovation and R&D

Environmental protection

We are committed to contributing to the cause of environmental protection and promoting sustainable development. We believe that through collaboration and innovation, we can create a cleaner and more sustainable environment for the future.

01

Electronic product manufacturing

The coating machine can be used for the spraying and coating of electronic product shells to ensure the appearance quality and protective performance.

02

Packaging industry

In the surface coating and coating of packaging materials, coater can provide efficient and accurate coating and coating services to meet different packaging needs.

03

Printing industry

The coating machine can be used for the surface coating and film of printed matter to improve the quality and durability of printed matter.

04

Construction industry

In the surface treatment of building materials, coater can provide fast and uniform coating and film, ensuring coating quality and product appearance.

coater

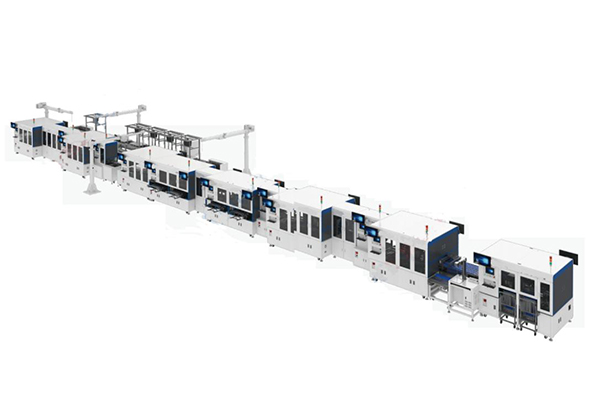

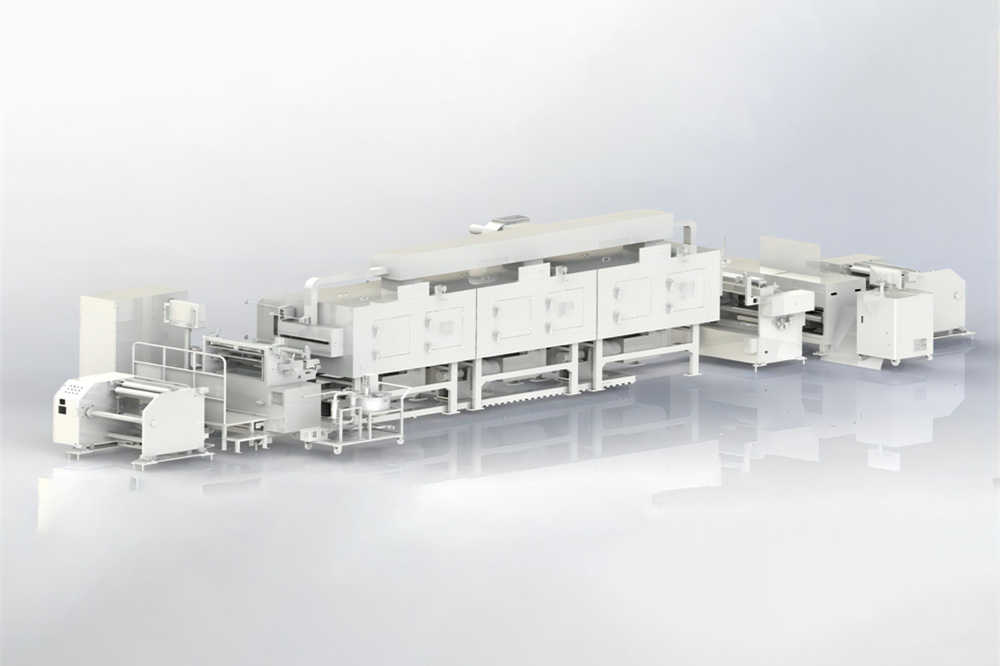

coater Advanced Extrusion Coater for High Quality Coating

Advanced Extrusion Coater for High Quality Coating High-Quality Transfer Coater for Smooth Coating

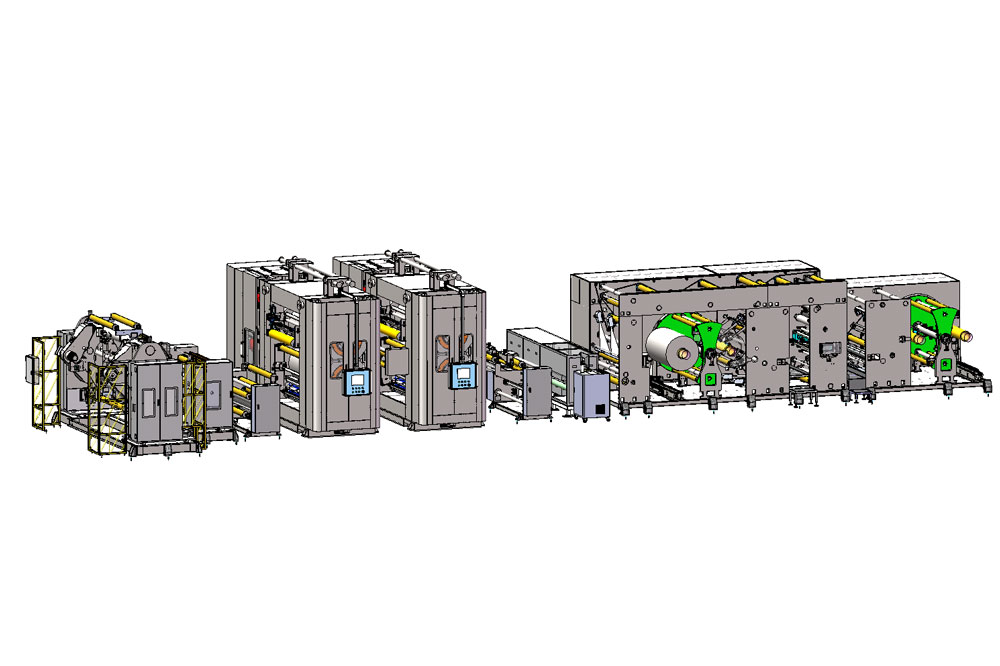

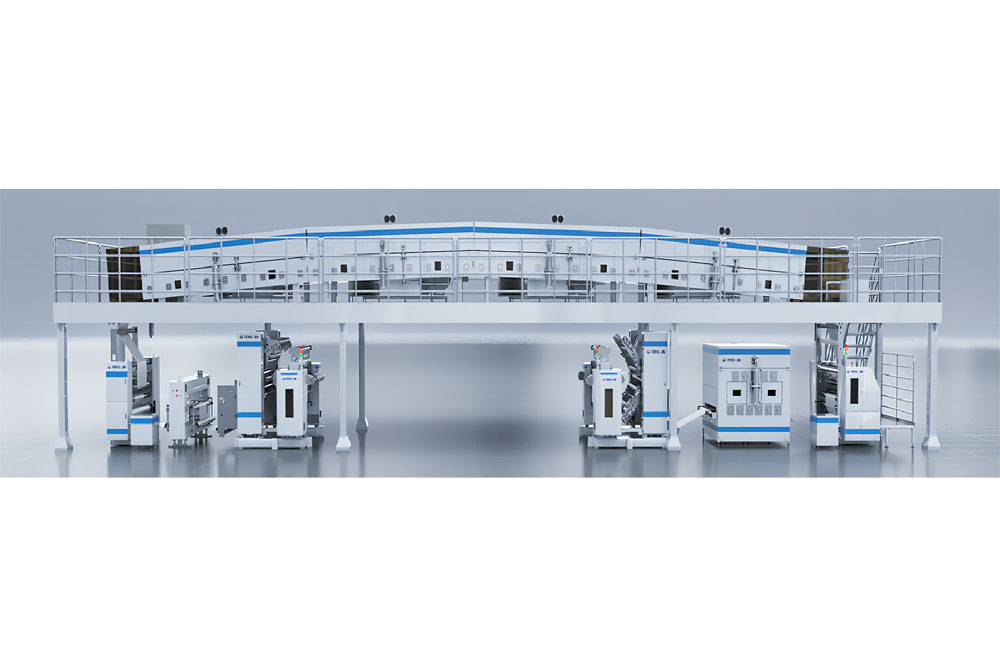

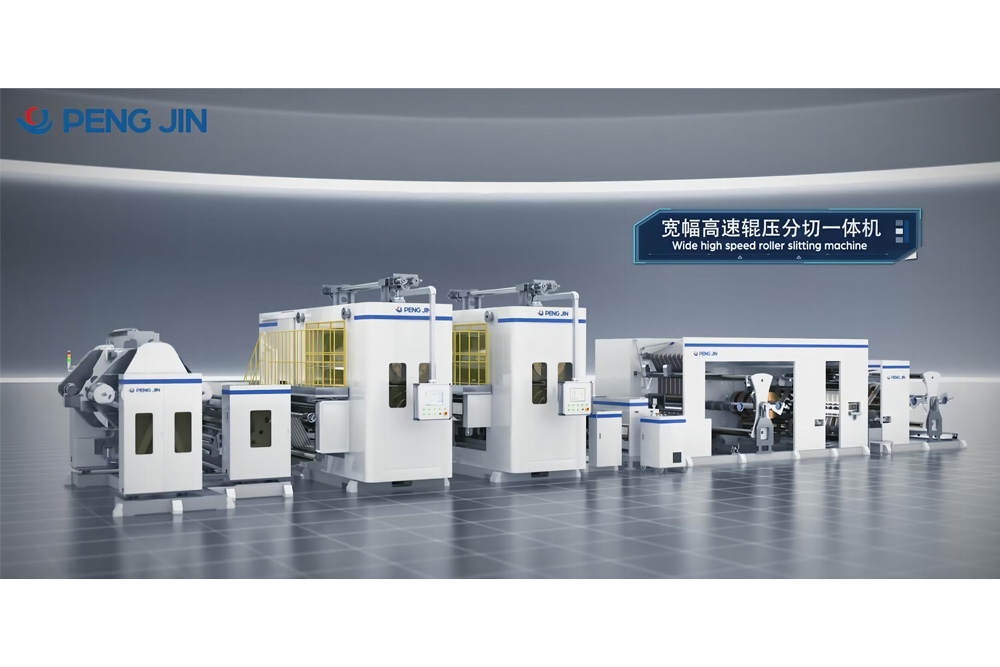

High-Quality Transfer Coater for Smooth Coating The double guide arm structure Gravure coater

The double guide arm structure Gravure coater The double guide arm structure Gravure coater

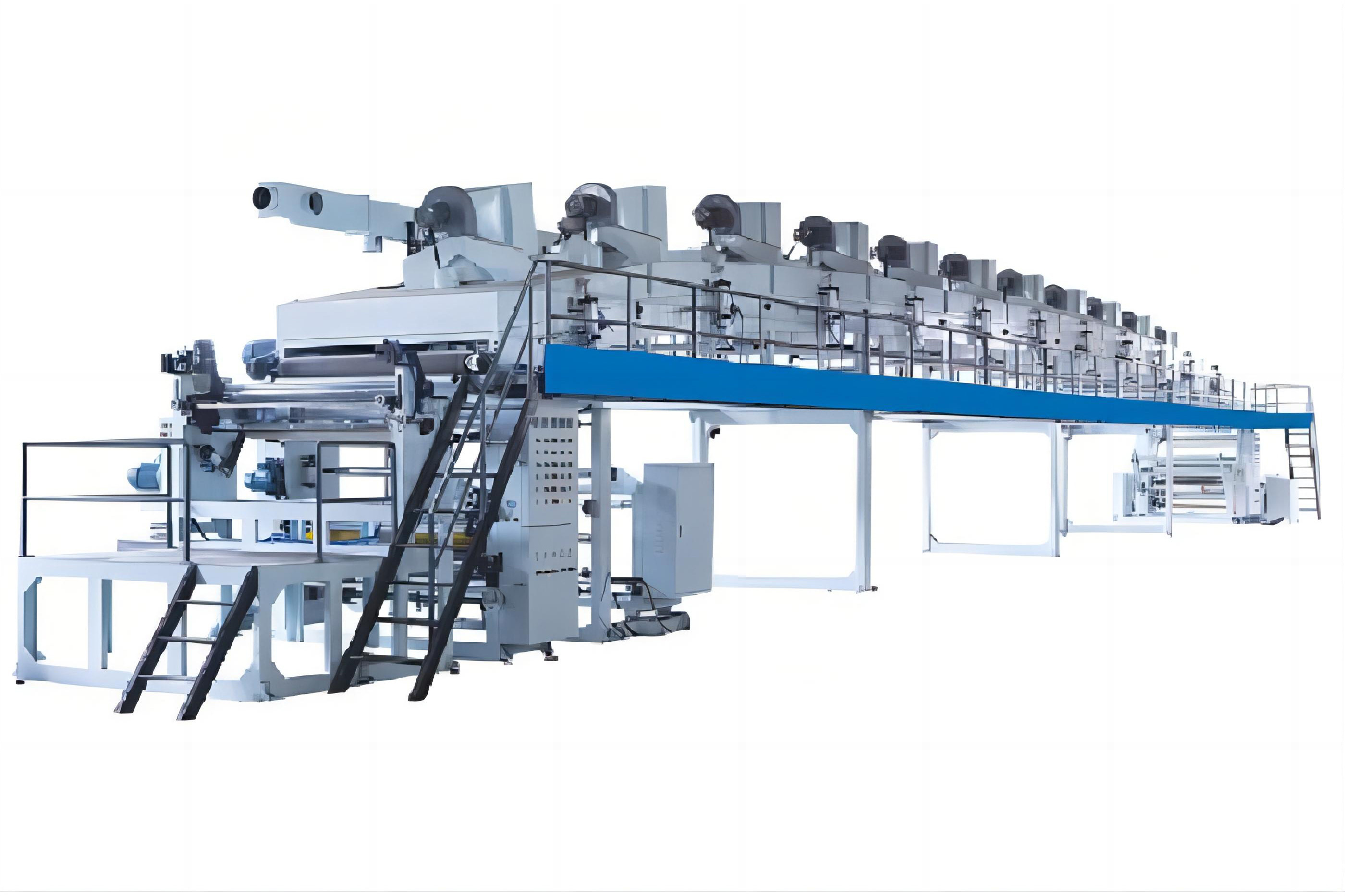

The double guide arm structure Gravure coater Enhanced Coating: High-Precision Micro-Concave Coater

Enhanced Coating: High-Precision Micro-Concave Coater Dry Electrode Diaphragm Calender

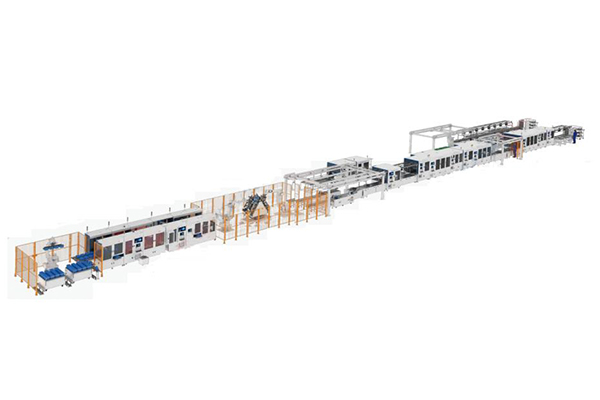

Dry Electrode Diaphragm Calender Hunan Desai NMP Distillation Equipment

Hunan Desai NMP Distillation Equipment Shaoxing Fudi NMP Distillation Equipment

Shaoxing Fudi NMP Distillation Equipment NMP distillation equipment in Ningguo era

NMP distillation equipment in Ningguo era Guangxi Fudi (Qingxiu) NMP Recovery System

Guangxi Fudi (Qingxiu) NMP Recovery System NMP Recovery Equipment in Desai, Hunan Province

NMP Recovery Equipment in Desai, Hunan Province Xiangyang Foday NMP Recovery System

Xiangyang Foday NMP Recovery System Shangrao SVOLT NMP Recovery System

Shangrao SVOLT NMP Recovery System Yongning FinDreams Battery NMP Recovery System

Yongning FinDreams Battery NMP Recovery System ASEAN Fodi (Wuming) NMP equipment recycling system

ASEAN Fodi (Wuming) NMP equipment recycling system Guangzhou Rongjie NMP recycling system

Guangzhou Rongjie NMP recycling system

WhatsApp

WhatsApp

Facebook

Facebook

Instagram

Instagram