Guangzhou Rongjie NMP recycling system

| Project: Guangzhou Rongjie NMP recycling system | ||||||||||||

| Customer demand parameter | Equipment parameter | |||||||||||

| Air volume: | 1#- positive electrode - 168,000 m³/h*4 1#- negative electrode -117600m³/h*4 5#- positive electrode -6000m³/h*1 5#- positive electrode -15000m³/h*2 5#- negative electrode -6000m³/h*1 5#- negative electrode -11000m³/h*2 Tank farm: Good liquid tank -150m³*2 Liquid waste tank -150m³*2 |

Equipment type | Treated air volume | Equipment size | NMP liquid recovery concentration | Runner material | Tail gas emission concentration | |||||

| Production line (positive and negative) : | 1#- positive electrode - 168,000 m³/h*4 1#- negative electrode -117600m³/h*4 5#- positive electrode -6000m³/h*1 5#- positive electrode -15000m³/h*2 5#- negative electrode -6000m³/h*1 5#- negative electrode -11000m³/h*2 Tank farm: Good liquid tank -150m³*2 Liquid waste tank -150m³*2 |

diameter | Altitude | |||||||||

| NMP liquid concentration: | ≥90% | PJNMP-168K PJNMP-117.6K PJNMP-6K PJNMP-15K PJNMP-6K PJNMP-11K |

168000m³/h 117600m³/h 6000m³/h 15000m³/h 6000m³/h 11000m³/h |

φ1050 φ650 |

/ | ≤300ppm | Zeolite molecular sieve | 1.457mg/m³ | ||||

| Heat transfer efficiency: | ≥85% | |||||||||||

| NMP gas exhaust index: | ≤10mg/m³,After activated carbon treatment≤1.457mg/m³ | |||||||||||

| Floor area: | 1#:1794㎡,5#:240㎡,Tank farm:1390㎡ | |||||||||||

| Process flow: waste heat recovery + condensation freezing + wheel + activated carbon treatment. | ||||||||||||

| Project features: This project is an automatic NMP recovery and treatment system for a tow with a large volume of air. Efficient waste heat recovery heat treatment, exhaust air for effective heat exchange. Cryogenic condensation, full recovery of NMP waste liquid. The zeolite seed is adsorbed by wheel and then adsorbed by activated carbon device to meet the discharge requirements. G4F8 impurities filter, ensure equipment and return air cleanliness. | ||||||||||||

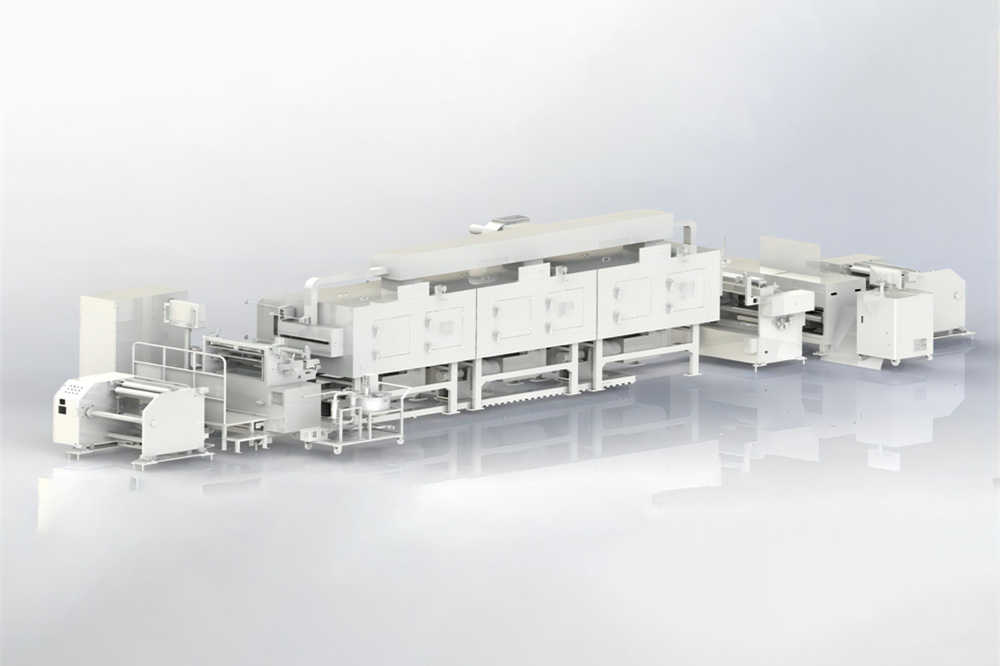

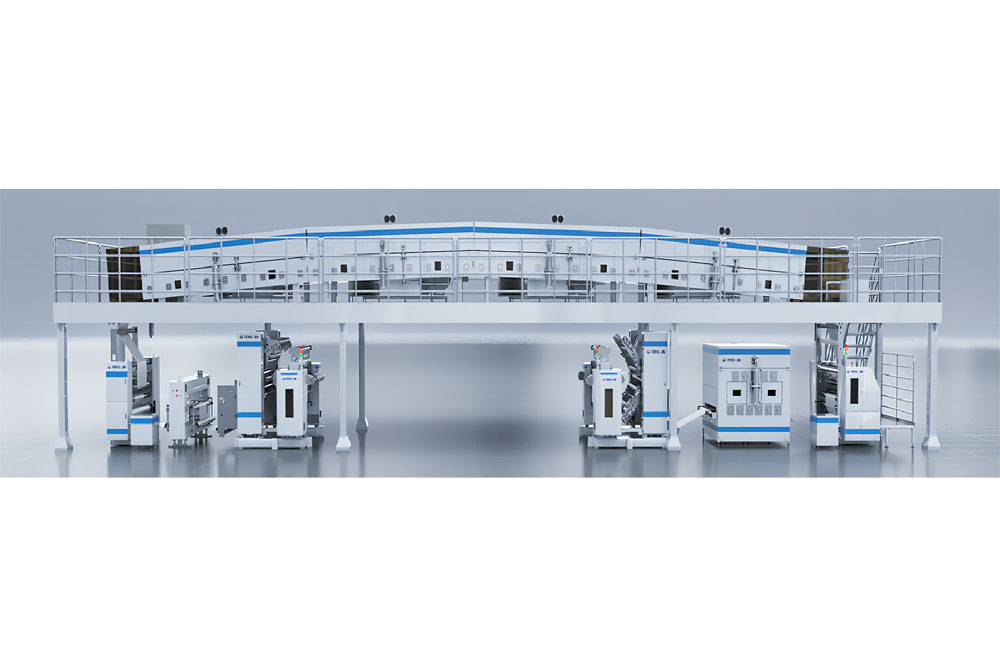

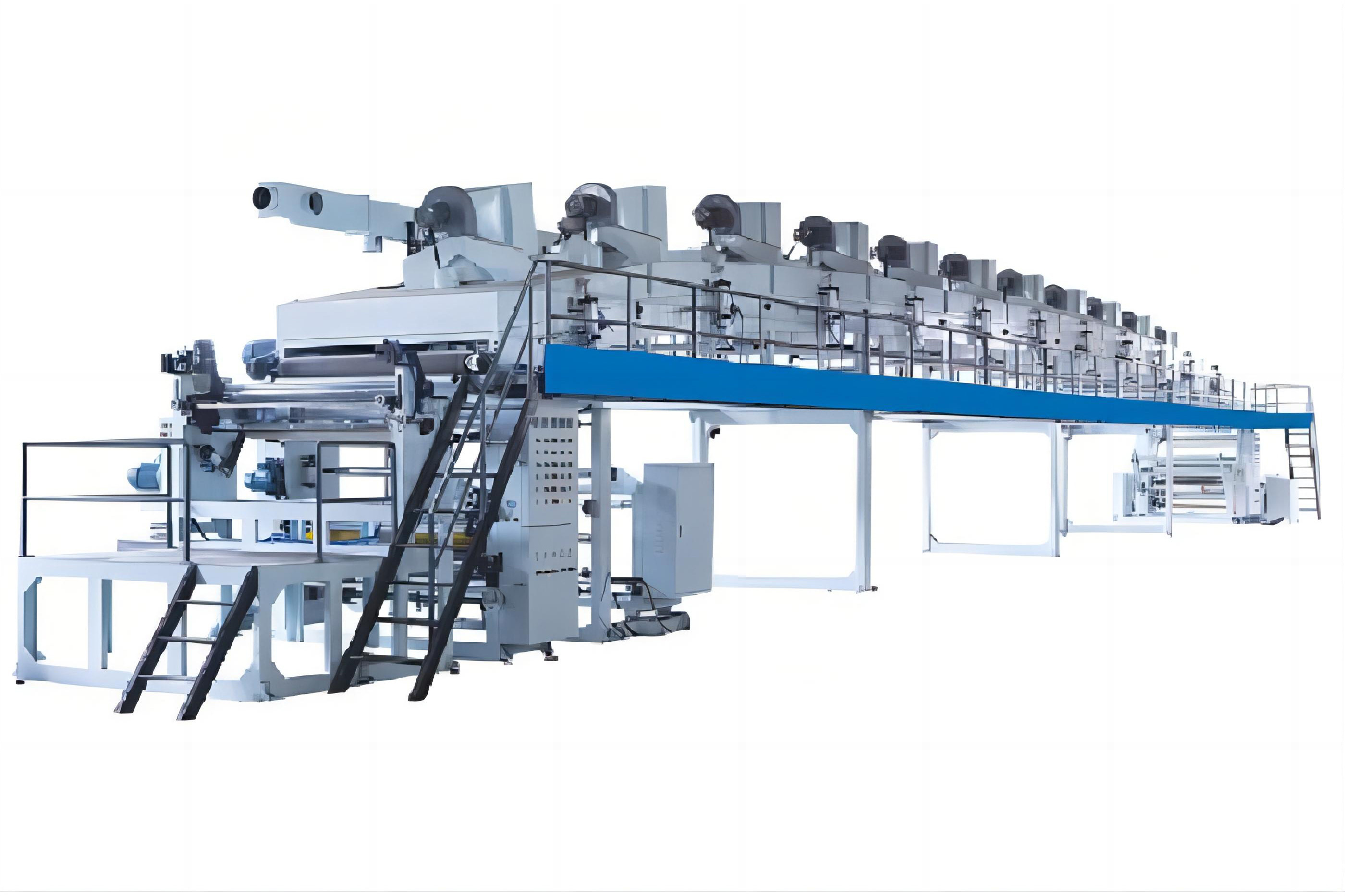

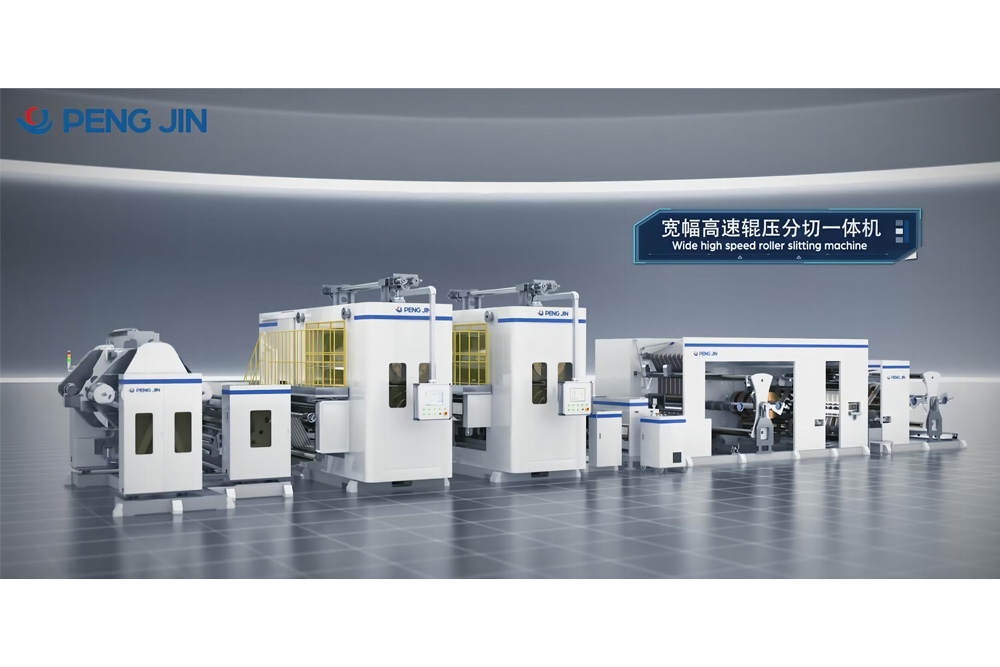

coater

coater Advanced Extrusion Coater for High Quality Coating

Advanced Extrusion Coater for High Quality Coating High-Quality Transfer Coater for Smooth Coating

High-Quality Transfer Coater for Smooth Coating The double guide arm structure Gravure coater

The double guide arm structure Gravure coater The double guide arm structure Gravure coater

The double guide arm structure Gravure coater Enhanced Coating: High-Precision Micro-Concave Coater

Enhanced Coating: High-Precision Micro-Concave Coater Dry Electrode Diaphragm Calender

Dry Electrode Diaphragm Calender Hunan Desai NMP Distillation Equipment

Hunan Desai NMP Distillation Equipment Shaoxing Fudi NMP Distillation Equipment

Shaoxing Fudi NMP Distillation Equipment NMP distillation equipment in Ningguo era

NMP distillation equipment in Ningguo era Guangxi Fudi (Qingxiu) NMP Recovery System

Guangxi Fudi (Qingxiu) NMP Recovery System NMP Recovery Equipment in Desai, Hunan Province

NMP Recovery Equipment in Desai, Hunan Province Xiangyang Foday NMP Recovery System

Xiangyang Foday NMP Recovery System Shangrao SVOLT NMP Recovery System

Shangrao SVOLT NMP Recovery System Yongning FinDreams Battery NMP Recovery System

Yongning FinDreams Battery NMP Recovery System ASEAN Fodi (Wuming) NMP equipment recycling system

ASEAN Fodi (Wuming) NMP equipment recycling system Guangzhou Rongjie NMP recycling system

Guangzhou Rongjie NMP recycling system

WhatsApp

WhatsApp

Facebook

Facebook

Instagram

Instagram