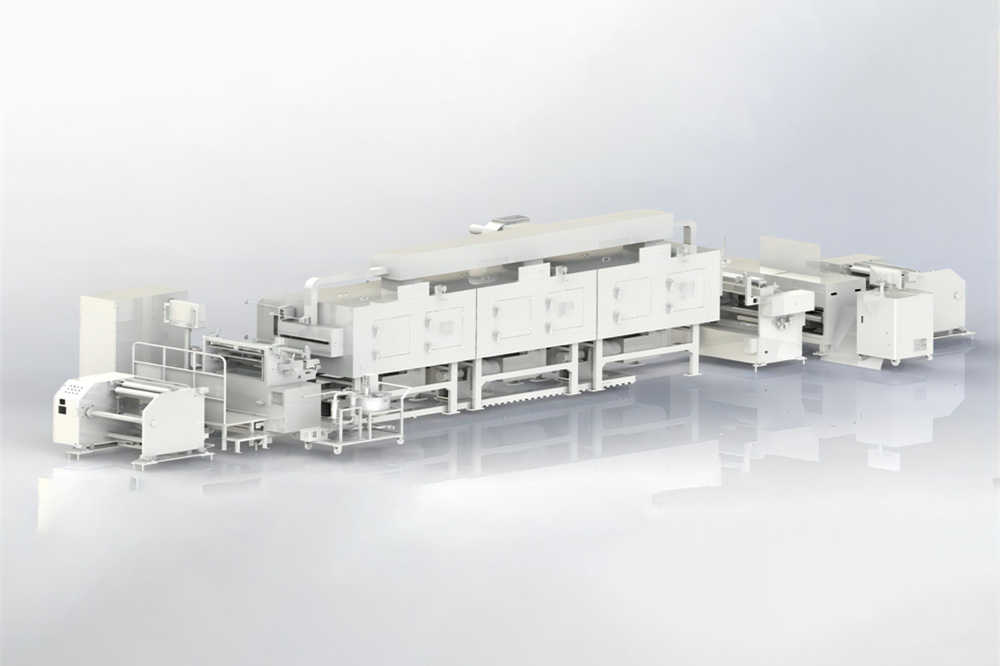

High-Quality Transfer Coater for Smooth Coating

Equipment advantages

Transfer Coater

1. By using a flexible scraper, the gap between the roller sleeve and the roller shaft can be adjusted by turning the adjusting screw on the roller sleeve, and then the straightness of the knife edge can be adjusted slightly to ensure the uniformity and controllability of the coating thickness of the pole piece.

2. Integrated axial steel roller structure, interference hot-fitting, integrated grinding, to ensure that the jump is less than or equal to ≤2.0um (laser detection), and the action balance treatment is more than G1 precision.

3. Double closed-loop tension control, tension swing roller adopts low friction cylinder, and tension fluctuation is ≤±2N.

4. Professional fluid analysis and design, independent return air cavity design, solve the problems of uneven drying, curling and overdrying on both sides and middle area of the pole piece.

5. Oven fluid simulation, specially designed pressure relief nozzle structure+multistage pressure equalizing cavity, the lateral wind speed fluctuation of a single nozzle is ≤±2% (measured), which improves drying consistency and reduces the risk of pole piece deviation in the oven.

FAQS

1. Q: How to change the scraper of coating machine?

A: The servo motor adjusts the cutter, and the roller bearing is at the lowest position. The spacer is padded between the comma roller and the coating roller, so as to touch it carefully and loosen all the fixed parts. Manually adjust the cutter to prevent the roller surface from contacting and then remove it.

2. Q: What are the key control parameters of the coater?

A: Unit speed, coating unit tension, drying equipment length, drying equipment characteristics, coating thickness, coating curing process related parameters and so on. 3. Q: Important points in coating process of coating machine.

3. Q: Important points in coating process of coating machine.

A: The first is the requirement for the quality of the coater blade, the second is the importance of the feeding system, the third is the jumping of the steel roller and cots, and the fourth is the stability and uniformity of the drying system.

4. Q: How to adjust the coating thickness of transfer coater?

A: The transfer of the weight and thickness of the coating film is mainly realized by adjusting the scraper gap and speed ratio, so the adjustment of the scraper gap is an important control point in the coating process. At present, the scraper gap adjustment method is divided into screw adjustment; At present, the advanced technology is imported displacement sensor detection, driven by servo motor, forming an automatic closed-loop adjustment of scraper gap. Generally, it is easy to adjust the scraper gap upward, but it fluctuates greatly downward.

5. Q: How does the transfer coater adjust the problem of head thinning?

A: Generally, it is used for intermittent coating, which can be affected by adjusting the thinning parameters and length of the head and tail, the gap between the steel roller and the rubber roller should be moderate, and the intermittent stroke, the leaving and closing time of the rubber roller will also be affected.

coater

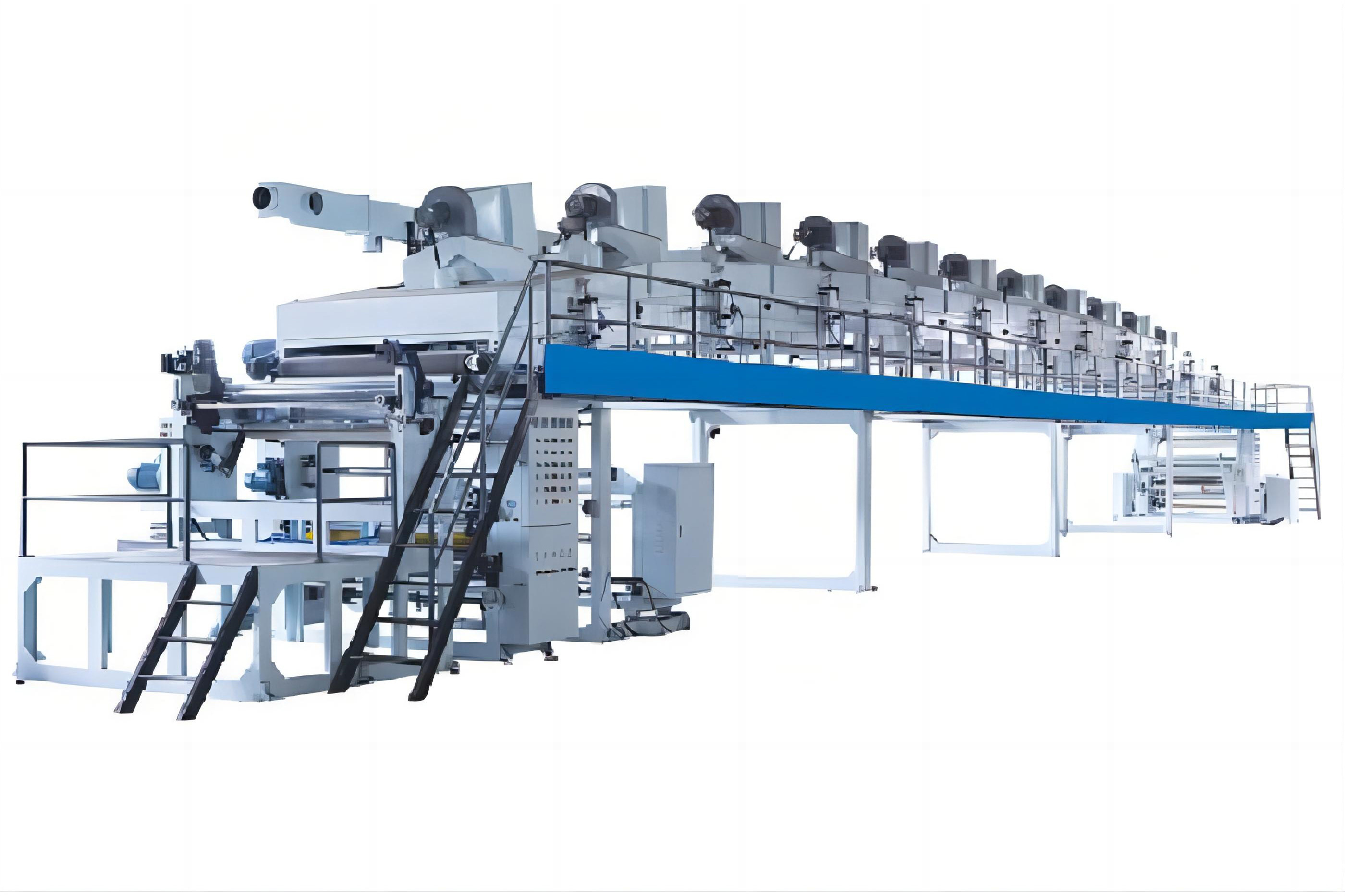

coater Advanced Extrusion Coater for High Quality Coating

Advanced Extrusion Coater for High Quality Coating High-Quality Transfer Coater for Smooth Coating

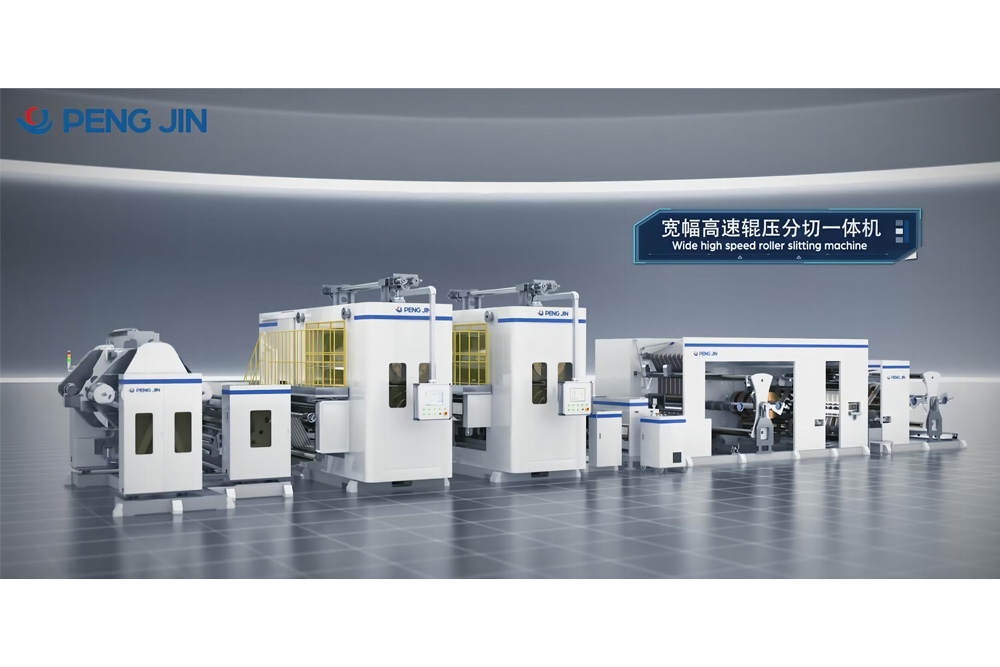

High-Quality Transfer Coater for Smooth Coating The double guide arm structure Gravure coater

The double guide arm structure Gravure coater The double guide arm structure Gravure coater

The double guide arm structure Gravure coater Enhanced Coating: High-Precision Micro-Concave Coater

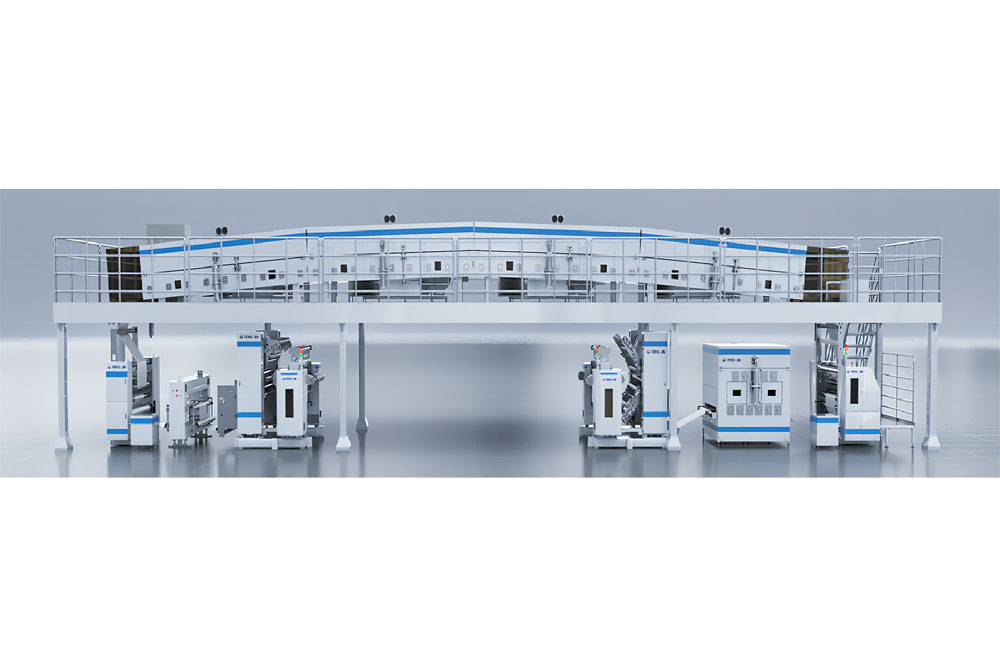

Enhanced Coating: High-Precision Micro-Concave Coater Dry Electrode Diaphragm Calender

Dry Electrode Diaphragm Calender Hunan Desai NMP Distillation Equipment

Hunan Desai NMP Distillation Equipment Shaoxing Fudi NMP Distillation Equipment

Shaoxing Fudi NMP Distillation Equipment NMP distillation equipment in Ningguo era

NMP distillation equipment in Ningguo era Guangxi Fudi (Qingxiu) NMP Recovery System

Guangxi Fudi (Qingxiu) NMP Recovery System NMP Recovery Equipment in Desai, Hunan Province

NMP Recovery Equipment in Desai, Hunan Province Xiangyang Foday NMP Recovery System

Xiangyang Foday NMP Recovery System Shangrao SVOLT NMP Recovery System

Shangrao SVOLT NMP Recovery System Yongning FinDreams Battery NMP Recovery System

Yongning FinDreams Battery NMP Recovery System ASEAN Fodi (Wuming) NMP equipment recycling system

ASEAN Fodi (Wuming) NMP equipment recycling system Guangzhou Rongjie NMP recycling system

Guangzhou Rongjie NMP recycling system

WhatsApp

WhatsApp

Facebook

Facebook

Instagram

Instagram