1.Tail gas emission concentration: The concentration of total non-methane hydrocarbons is ≤ 50mg/m³, how can your company achieve 20mg/m³?

After being cooled and condensed by the condenser, a small part of the exhaust gas enters the spray tower for circular rinsing and absorption treatment or the rotary wheel for circular adsorption and regeneration treatment, which has completely met the national standard of ≤ 50mg/m³ or even reached 20mg/m³, and the third-party exhaust gas detection report can meet the customer's requirements.

There are three layers of spray sections in the spray tower, and the corresponding spray section devices are designed according to the project requirements, and the tower bottom liquid is continuously sprayed by a water pump. When the liquid concentration reaches the set value, it flows into the waste liquid system, and the gas discharged from the top of the tower meets the environmental protection requirements and customer requirements.

VOCS zeolite molecular sieve runner is divided into adsorption treatment zone, cooling zone and desorption zone, and driven by motor, which makes the runner rotate slowly, supplemented by condensation cooling and heating device, and continuously adsorbs and regenerates, and the discharged gas meets the requirements of environmental protection and customers.

2.Can your NMP recovery rate reach over 90%?

The recovery rate of NMP recovery equipment in our company is ≥99%, and the specific calculation scheme is as follows (calculated according to the actual data of the project):

Recovery rate =1-{(Recovery system terminal exhaust air volume * Exhaust concentration)/( Inlet air volume of recovery system * Inlet concentration)}

3.How to approve the heat exchange efficiency of your waste heat recovery equipment?

Heat exchange efficiency = (Cold flow outlet temperature - Cold flow inlet temperature)/(Heat flow inlet temperature - Cold flow inlet temperature)

Through the continuous research of our technology, our waste heat recovery equipment has cross-shaped, X-shaped and countercurrent type, and the heat exchange efficiency can reach up to 90%, which is far ahead in the industry and provides customers with more choices.

4.The reserved amount of chilled water in the previous plant design is less. Do you have any improvement plans to meet the use of the treatment system?

We can consider using waste heat recovery equipment with high heat exchange efficiency to reduce the consumption of chilled water.

5.The design of civil foundation and steel structure platform for waste gas treatment was not taken into account in the previous workshop design. Do you have the design and installation ability in this respect?

Our company has the ability in this field, including exhaust gas treatment system design and installation, electrical control system design and installation, civil engineering foundation design and construction, steel structure design and installation, which can cooperate with each other to provide customers with solutions, and can also be used for 3D exhibition review to provide better services to customers. Several projects have been completed and used safely and stably.

6.What is your plan for controlling the concentration of return air?

According to the return air concentration demand of customers, customers are required to provide chilled water at 7℃-12℃, and the chilled water temperature must be stable enough. When the chilled water temperature has a small deviation or the water temperature is unstable, we should consider improving the heat exchange efficiency of waste heat recovery equipment to meet the demand of return air concentration.

7.How to ensure the humidity requirement of return air?

A closed circulation system can be considered, that is, the exhaust and return air do not contact with the outside air, and the treatment system does not introduce fresh air. The air contains a certain amount of moisture, and the density of water vapor in the high-temperature gas discharged by the coater is also high. The condensing host also treats the water vapor when cooling and condensing the compound. The condensing host is additionally provided with a defogging device, which can effectively intercept and collect water bubbles in the air, and reasonably ensure the humidity requirements of the return air according to the working capacity of the condensing host.

8.What's the difference between using high tower or rotating wheel in NMP recycling system?

The following are some comparison points between high tower and runner. Reasonable NMP recycling solution should be formulated according to the factory conditions or actual needs of customers to achieve a win-win situation.

Tower system:

①It occupies a large space and needs to be laid outdoors (which may involve civil foundation, equipment steel platform, tail gas emission cage frame, etc.), so the initial investment is relatively large.

②Low energy consumption, less demand for water and electricity consumption.

③The recovery rate of NMP is lower, and the emission concentration of tail gas is higher.

Runner system:

①The floor space is small, and it can be arranged in the workshop indoor interlayer with small initial investment.

②Energy consumption is high, and the amount of heating devices (electric heating, steam heating and heat transfer oil heating) is in great demand.

③The recovery rate of NMP is higher and the emission concentration of tail gas is lower. Under the demand of lower emission concentration, the built-in double-wheel type can be used to meet the emission requirements, and the demand space is small.

9.Hydrofluoric acid (HF) solution will be produced in the treatment of electrolyte waste gas, which has strong acidity and corrosive influence on stainless steel and other products. What is your solution?

Consider adding a hydrofluoric acid solution neutralization device (mainly composed of industrial alkali solution (low concentration sodium hydroxide NaOH/NaHCO₃)) for neutralization.

10.What parameters can your electrical control system monitor?

According to the customer's demand, it can realize real-time monitoring of parameters such as wind speed, wind pressure, temperature, concentration, motor operating frequency, flow rate and liquid level, and also realize the functions of one-button start-stop of the system, automatic control, alarm and data management.

11.How to ensure the normal operation of outdoor system in snowy season?

In view of the snowy weather, according to the meteorological conditions where the project is located, the operation characteristics of each equipment, the medium characteristics of each pipeline and other factors, our company designed anti-freezing measures such as bypass pipeline, pipeline heat tracing and insulation, equipment heat tracing and insulation, and rain and snow shelter to ensure the normal operation of the system.

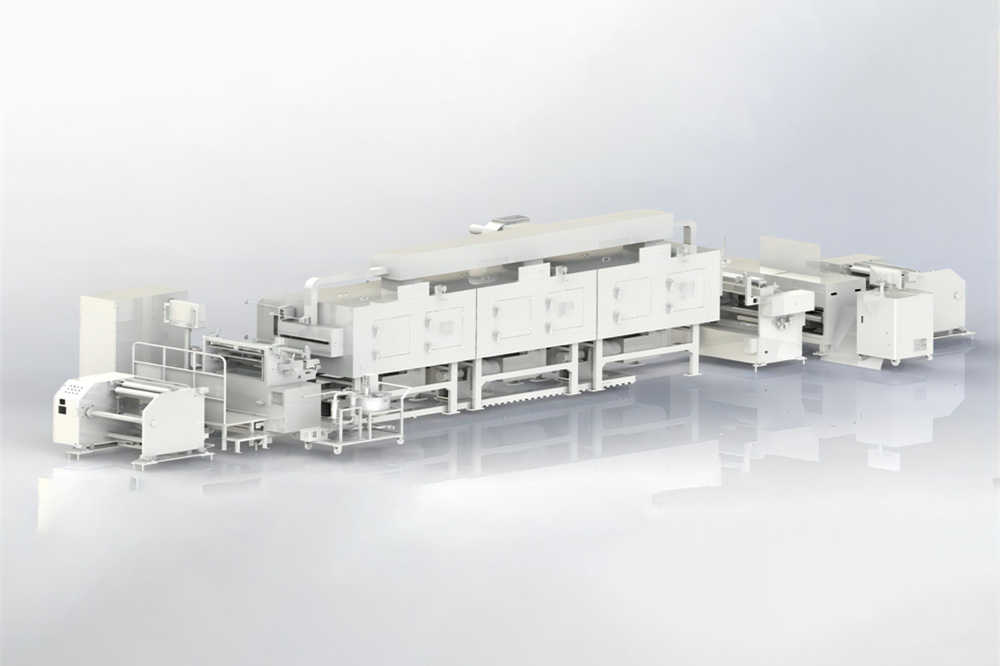

coater

coater Advanced Extrusion Coater for High Quality Coating

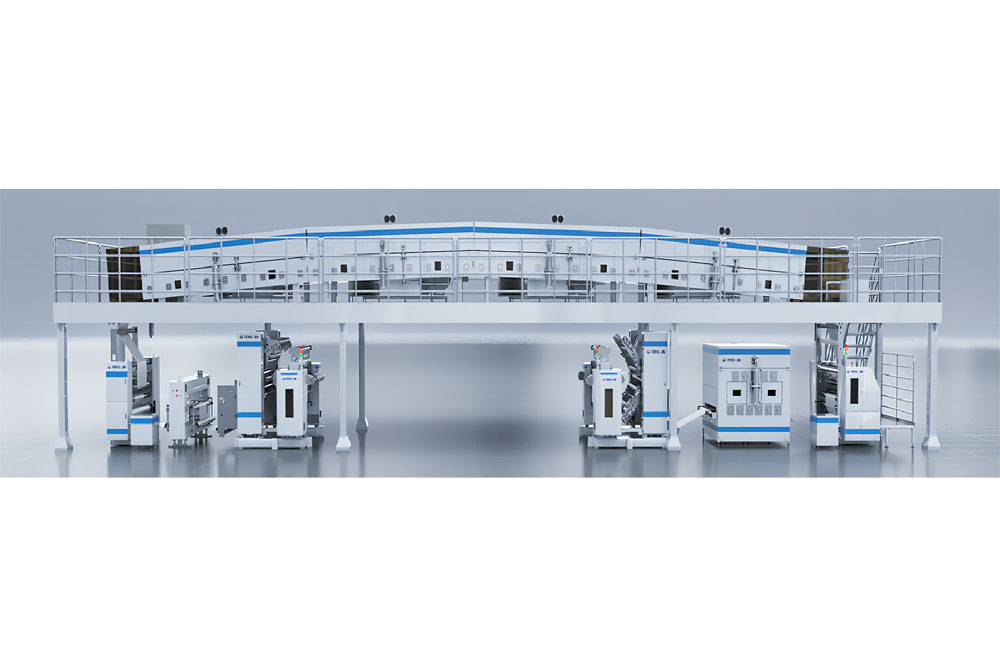

Advanced Extrusion Coater for High Quality Coating High-Quality Transfer Coater for Smooth Coating

High-Quality Transfer Coater for Smooth Coating The double guide arm structure Gravure coater

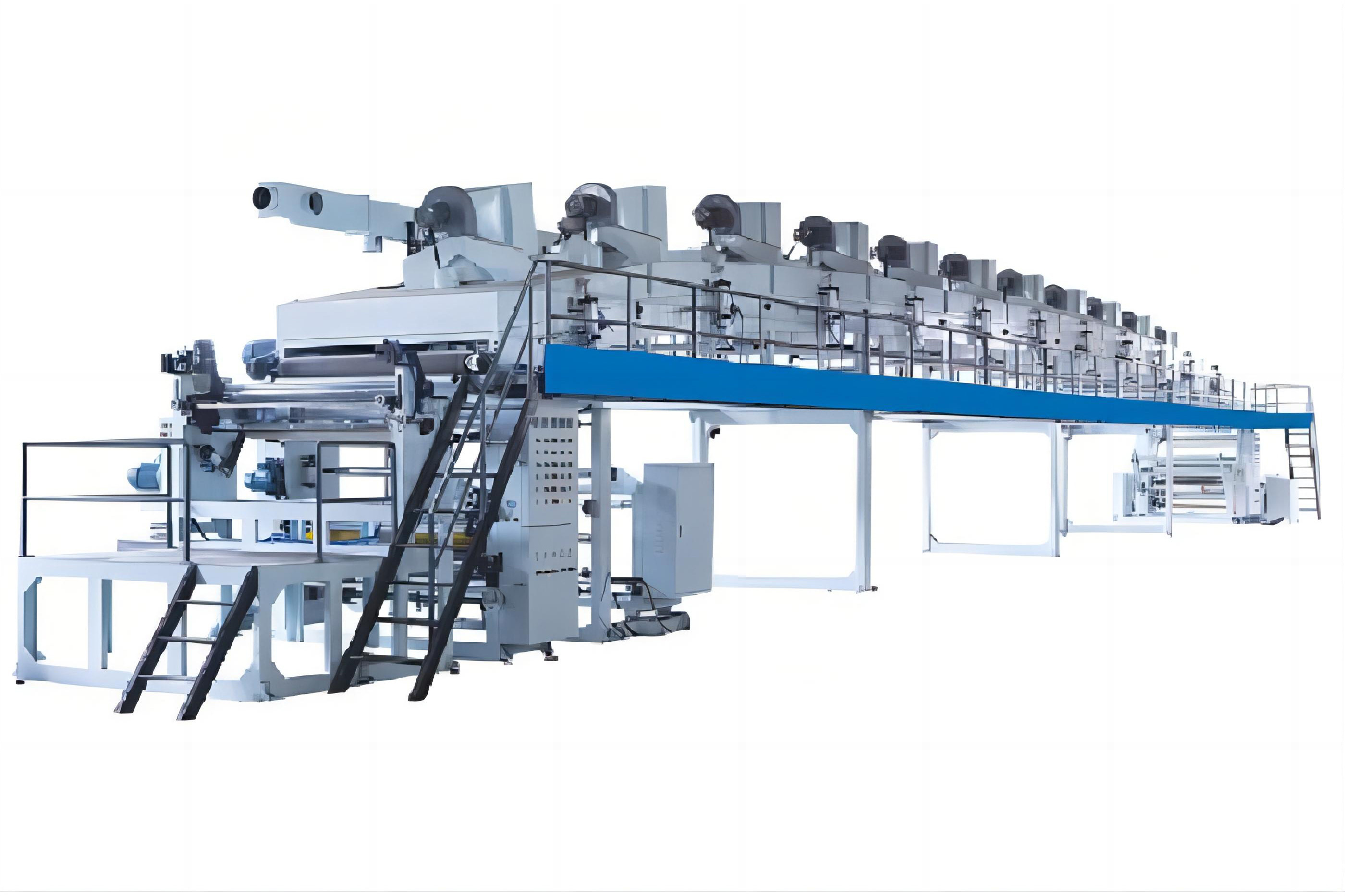

The double guide arm structure Gravure coater The double guide arm structure Gravure coater

The double guide arm structure Gravure coater Enhanced Coating: High-Precision Micro-Concave Coater

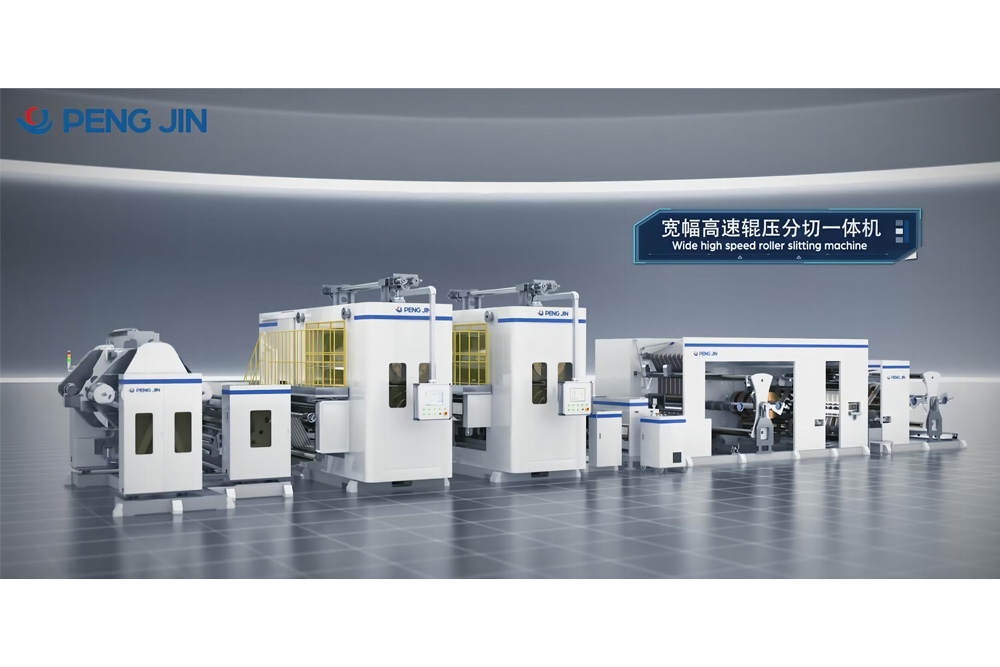

Enhanced Coating: High-Precision Micro-Concave Coater Dry Electrode Diaphragm Calender

Dry Electrode Diaphragm Calender Hunan Desai NMP Distillation Equipment

Hunan Desai NMP Distillation Equipment Shaoxing Fudi NMP Distillation Equipment

Shaoxing Fudi NMP Distillation Equipment NMP distillation equipment in Ningguo era

NMP distillation equipment in Ningguo era Guangxi Fudi (Qingxiu) NMP Recovery System

Guangxi Fudi (Qingxiu) NMP Recovery System NMP Recovery Equipment in Desai, Hunan Province

NMP Recovery Equipment in Desai, Hunan Province Xiangyang Foday NMP Recovery System

Xiangyang Foday NMP Recovery System Shangrao SVOLT NMP Recovery System

Shangrao SVOLT NMP Recovery System Yongning FinDreams Battery NMP Recovery System

Yongning FinDreams Battery NMP Recovery System ASEAN Fodi (Wuming) NMP equipment recycling system

ASEAN Fodi (Wuming) NMP equipment recycling system Guangzhou Rongjie NMP recycling system

Guangzhou Rongjie NMP recycling system

WhatsApp

WhatsApp

Facebook

Facebook

Instagram

Instagram