Waste Heat Recovery

About R&d innovationWaste Heat Recovery is the process of recovering the thermal energy contained in the exhaust gases of the coating production process, thereby achieving energy savings and reducing consumption. The principle involves using a heat exchanger to exchange heat between the high-temperature exhaust air from the system and the lower-temperature intake air, allowing the heat energy discharged from the high-temperature system to be returned to the system in the form of increased air temperature. This achieves the effect of heat recovery, increases the efficiency of thermal energy recycling, and reduces energy consumption and energy input.

The advantage of Pengjin's waste heat recovery system is that it maintains a relatively compact structure while leading the industry in waste heat recovery efficiency.

The Integrated Machine

About R&d innovationThe Integrated Machine is a system that simultaneously achieves three functions in the coating production process: purification of exhaust gases, waste heat recovery, and condensation of NMP gas into liquid for recycling.

The principle involves integrating three functional modules: a filtration box, waste heat recovery, and a condenser unit. This allows for the purification of exhaust air, recovery of thermal energy, and condensation and recovery of NMP gas during the coating production process.

The advantage of Pengjin's Integrated Machine is its compact footprint, high space utilization, and smoother gas flow.

The Activated Carbon Adsorption Box

About R&d innovationThe Activated Carbon Adsorption Box is used to separate and purify the mixture in the exhaust gases generated during the coating production process, allowing the exhaust gases to be safely discharged into the ambient atmosphere.

The principle is based on the physical and chemical adsorption characteristics of porous activated carbon. When the exhaust gases enter the activated carbon adsorption box and pass through its porous activated carbon layer, the interaction between the pollutants in the exhaust gases and the activated carbon effectively removes or attaches these substances to the surface of the activated carbon. This achieves the purification of air and improves air quality.

The advantage of Pengjin's Activated Carbon Adsorption Box lies in its industry-leading purification effectiveness.

High Efficiency

About R&d innovationThe sequential connection of the waste liquid recovery device, dehydration device, and distillation device forms an efficient system. The rotary recovery unit is connected to the NMP waste liquid recovery tank via the first feeding pipeline. The NMP waste liquid recovery tank is connected to the dehydration tower through the second feeding pipeline. The dehydration and reboiling pipeline is connected in sequence to the dehydration bottom pump and the dehydration reboiler, which allows the outlet of the dehydration tower and the lower reflux inlet to be connected. The outlet of the dehydration bottom pump is connected to the feed inlet of the distillation tower via the third feeding pipeline. The distillation tower has a side offtake outlet, which is connected to the recovery pipeline. This prevents incomplete removal of light components, which could result in the recovery of NMP products that do not meet specifications. As a result, it improves the qualification rate of the products and reduces equipment investment.

System and Process

About R&d innovationThis pertains to the technical domain of supporting equipment for lithium-ion battery production. The system comprises a heating kettle, a distillation tower, a Roots fan, a buffer tank, a molecular sieve membrane assembly, a condenser, a wastewater receiving tank, a product receiving tank, a vacuum buffer tank, and a vacuum pump. The heating kettle is utilized for heating the NMP waste liquid that requires purification, and it incorporates a gas distributor at the bottom. The gas outlet at the top is connected to both the distillation tower and the molecular sieve membrane assembly. The gas inlet of the gas distributor is linked to the Roots fan. The molecular sieve membrane assembly serves to separate NMP and water molecules from the circulating process gas. The process presented by this innovation accomplishes NMP purification by circulating and eliminating water in the form of a gas phase through the regulation of osmotic pressure and the pressure exerted by the Roots fan.

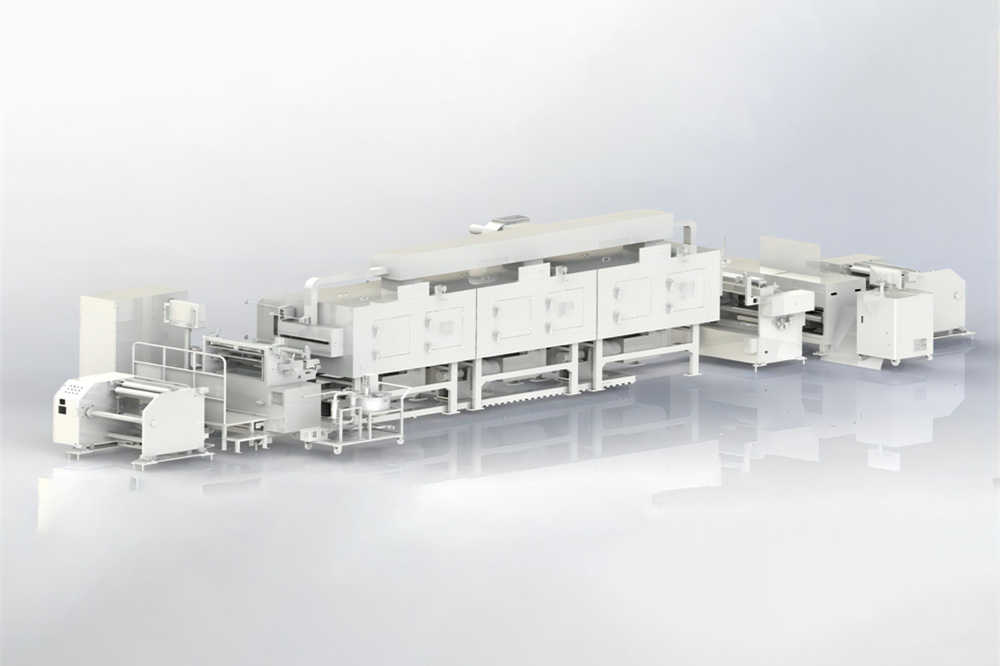

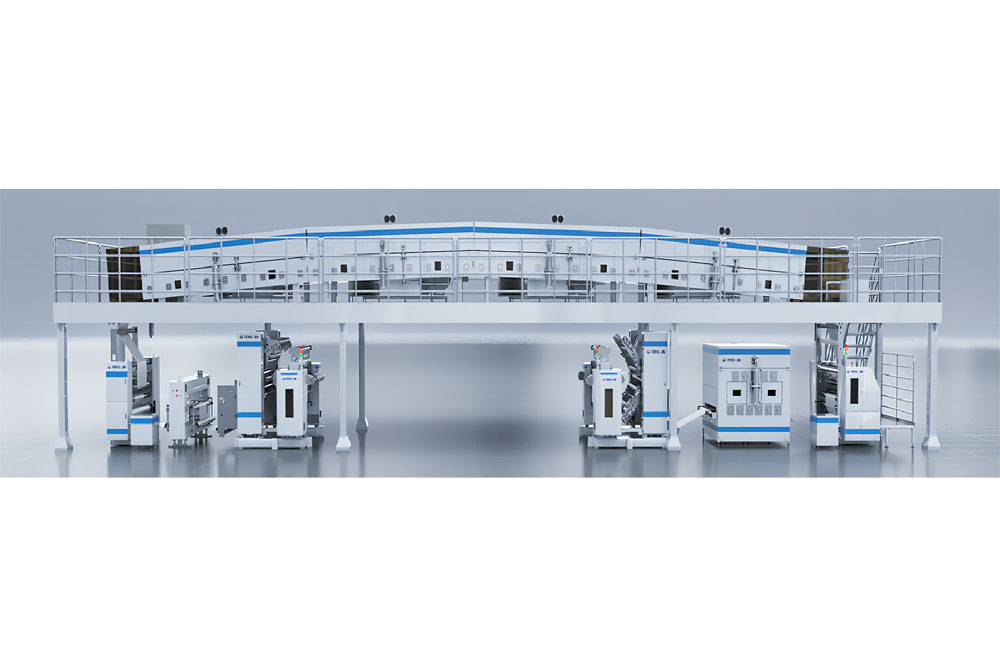

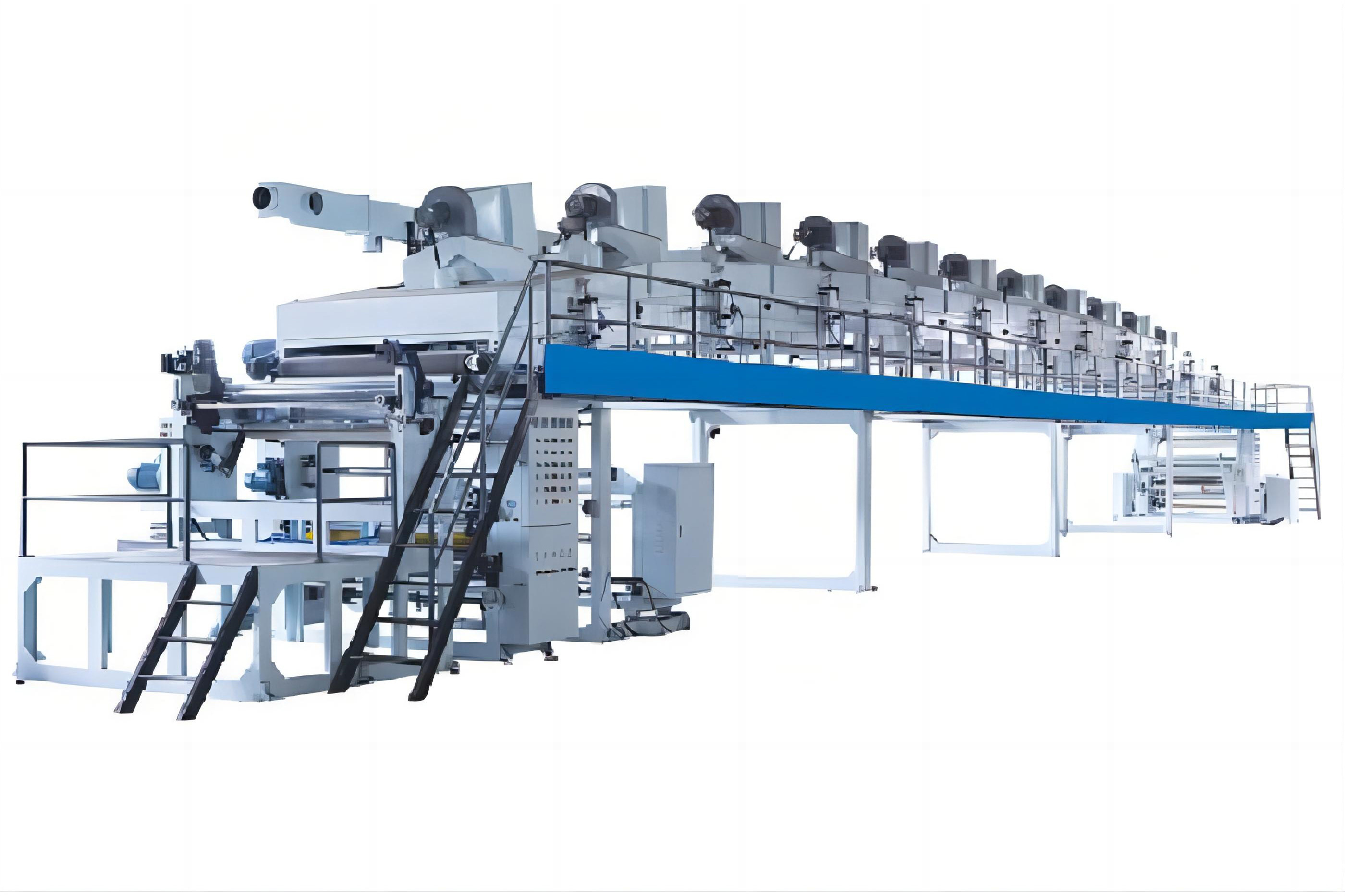

coater

coater Advanced Extrusion Coater for High Quality Coating

Advanced Extrusion Coater for High Quality Coating High-Quality Transfer Coater for Smooth Coating

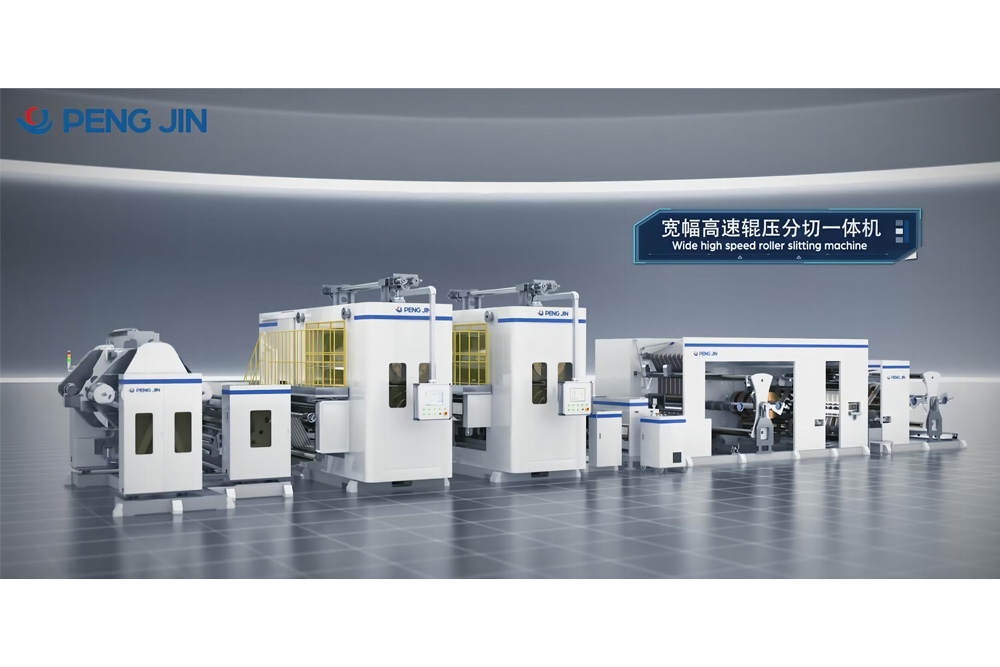

High-Quality Transfer Coater for Smooth Coating The double guide arm structure Gravure coater

The double guide arm structure Gravure coater The double guide arm structure Gravure coater

The double guide arm structure Gravure coater Enhanced Coating: High-Precision Micro-Concave Coater

Enhanced Coating: High-Precision Micro-Concave Coater Dry Electrode Diaphragm Calender

Dry Electrode Diaphragm Calender Hunan Desai NMP Distillation Equipment

Hunan Desai NMP Distillation Equipment Shaoxing Fudi NMP Distillation Equipment

Shaoxing Fudi NMP Distillation Equipment NMP distillation equipment in Ningguo era

NMP distillation equipment in Ningguo era Guangxi Fudi (Qingxiu) NMP Recovery System

Guangxi Fudi (Qingxiu) NMP Recovery System NMP Recovery Equipment in Desai, Hunan Province

NMP Recovery Equipment in Desai, Hunan Province Xiangyang Foday NMP Recovery System

Xiangyang Foday NMP Recovery System Shangrao SVOLT NMP Recovery System

Shangrao SVOLT NMP Recovery System Yongning FinDreams Battery NMP Recovery System

Yongning FinDreams Battery NMP Recovery System ASEAN Fodi (Wuming) NMP equipment recycling system

ASEAN Fodi (Wuming) NMP equipment recycling system Guangzhou Rongjie NMP recycling system

Guangzhou Rongjie NMP recycling system

WhatsApp

WhatsApp

Facebook

Facebook

Instagram

Instagram