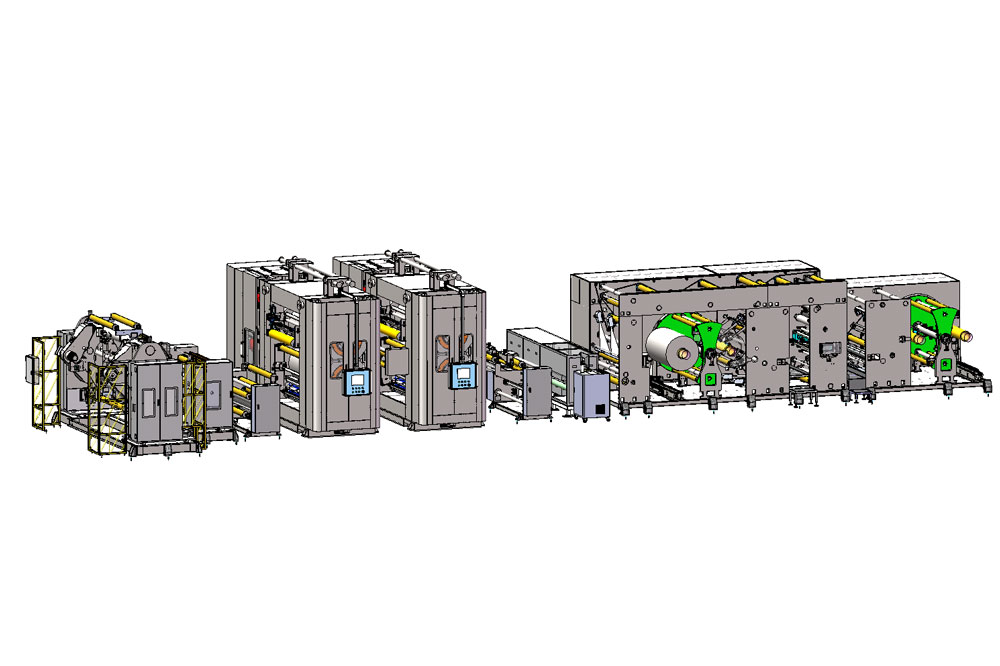

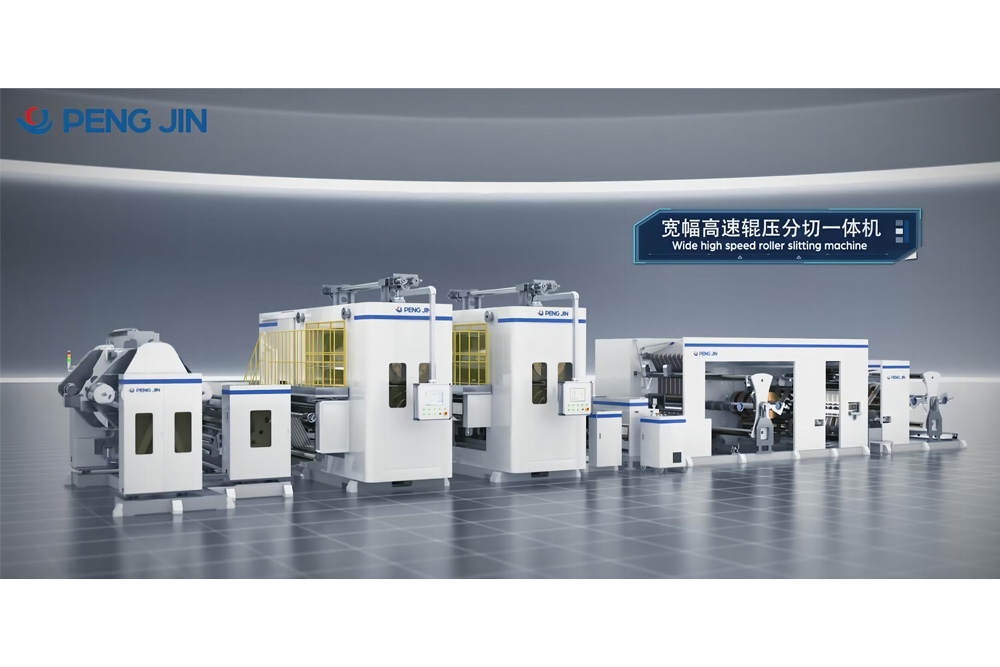

Roll-to-Sheet Integrated Machine

Equipment advantages

Roll-To-Sheet Integrated Machine

1. The expansion and contraction guidance of the pneumatic chuck adopts a guide rail mode, which is wear-resistant, has strong load-bearing capacity, and high reliability.

2. Innovative bending cylinder technology achieves the design goal of small bending force and large bending deformation.

3. The roller transmission adopts a ball cage coupling design, reducing the width of the roll pressing main unit by approximately 500mm, resulting in a smaller size and lower cost.

4. The integrated design of the front stretching mechanism with the preheating mechanism, and the rear stretching mechanism with the cooling mechanism, significantly reduces the belt travel distance and reduces the risk of belt wrinkles.

5. Optimized design of the heating oil passage for hot rolling rollers improves the uniformity of roller surface temperature (≤±1℃).

6. Based on the deformation deflection curve, the rollers are designed as curved rollers to ensure consistent thickness of the electrode sheet under roll pressure.

7. Independent upper knife design enables convenient adjustment, quick knife replacement without belt interruption, short changeover time, and low cost.

8. Rational optimization of mechanical structure, with some mechanisms equipped with quick disassembly functions (such as rollers, brushes, non-woven fabrics, magnetic bars).

9. Roller replacement time ≤4 hours/4 persons.

FAQS

Q: Why is the thickness of the electrode sheet uneven after roll pressing?

A: It may be due to uneven roll pressing pressure or unstable roll pressing speed of the equipment.

Q: Why is the thickness of the electrode sheet uneven transversely after roll pressing?

A: It may be caused by misalignment in the installation of the rolling machine's rollers or uneven surface of the rollers.

Q: Why is the thickness of the electrode sheet uneven longitudinally after roll pressing?

A: It may be due to uneven roll pressing pressure or unstable roll pressing speed of the rollers.

Q: Why does the electrode sheet exhibit crescent-shaped bending after roll pressing?

A: It may be caused by uneven roll pressing pressure or uneven surface of the rollers.

Q: Why does the electrode sheet have wavy edges after roll pressing?

A: It may be caused by uneven roll pressing pressure or unstable roll pressing speed.

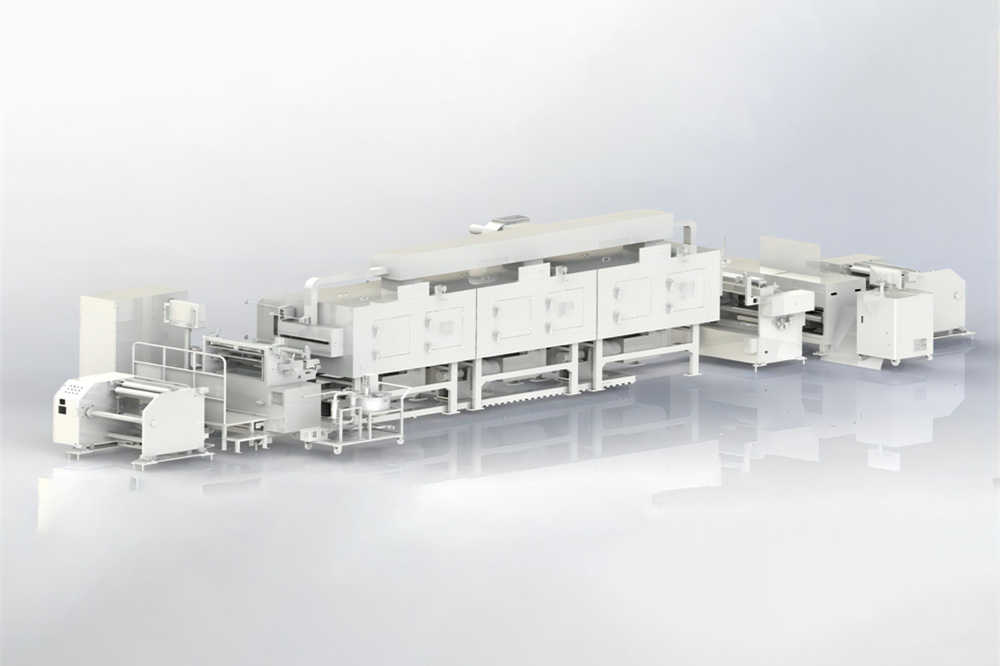

coater

coater Advanced Extrusion Coater for High Quality Coating

Advanced Extrusion Coater for High Quality Coating High-Quality Transfer Coater for Smooth Coating

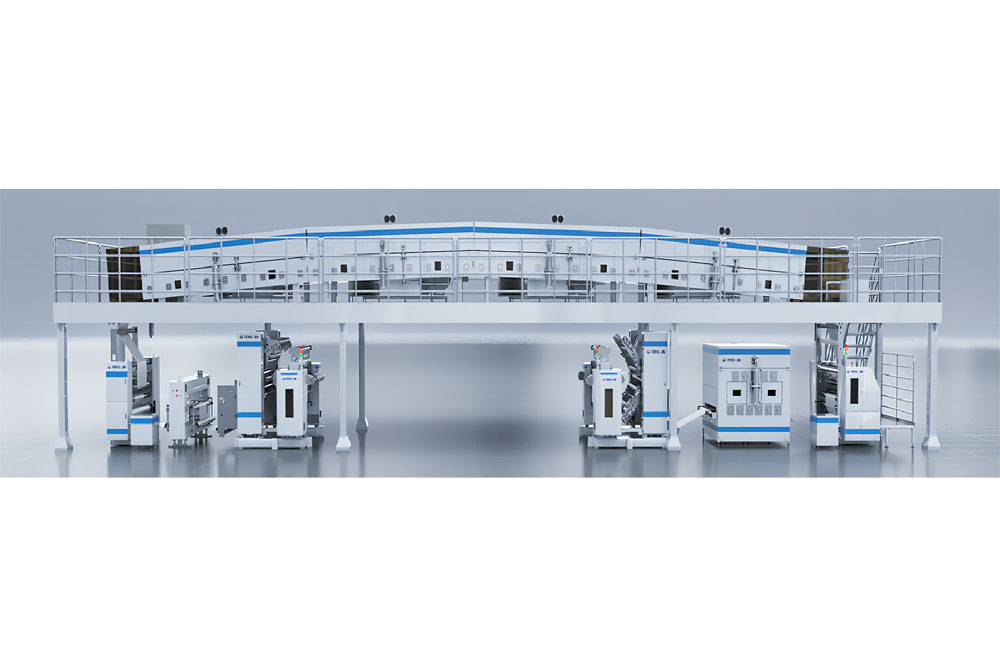

High-Quality Transfer Coater for Smooth Coating The double guide arm structure Gravure coater

The double guide arm structure Gravure coater The double guide arm structure Gravure coater

The double guide arm structure Gravure coater Enhanced Coating: High-Precision Micro-Concave Coater

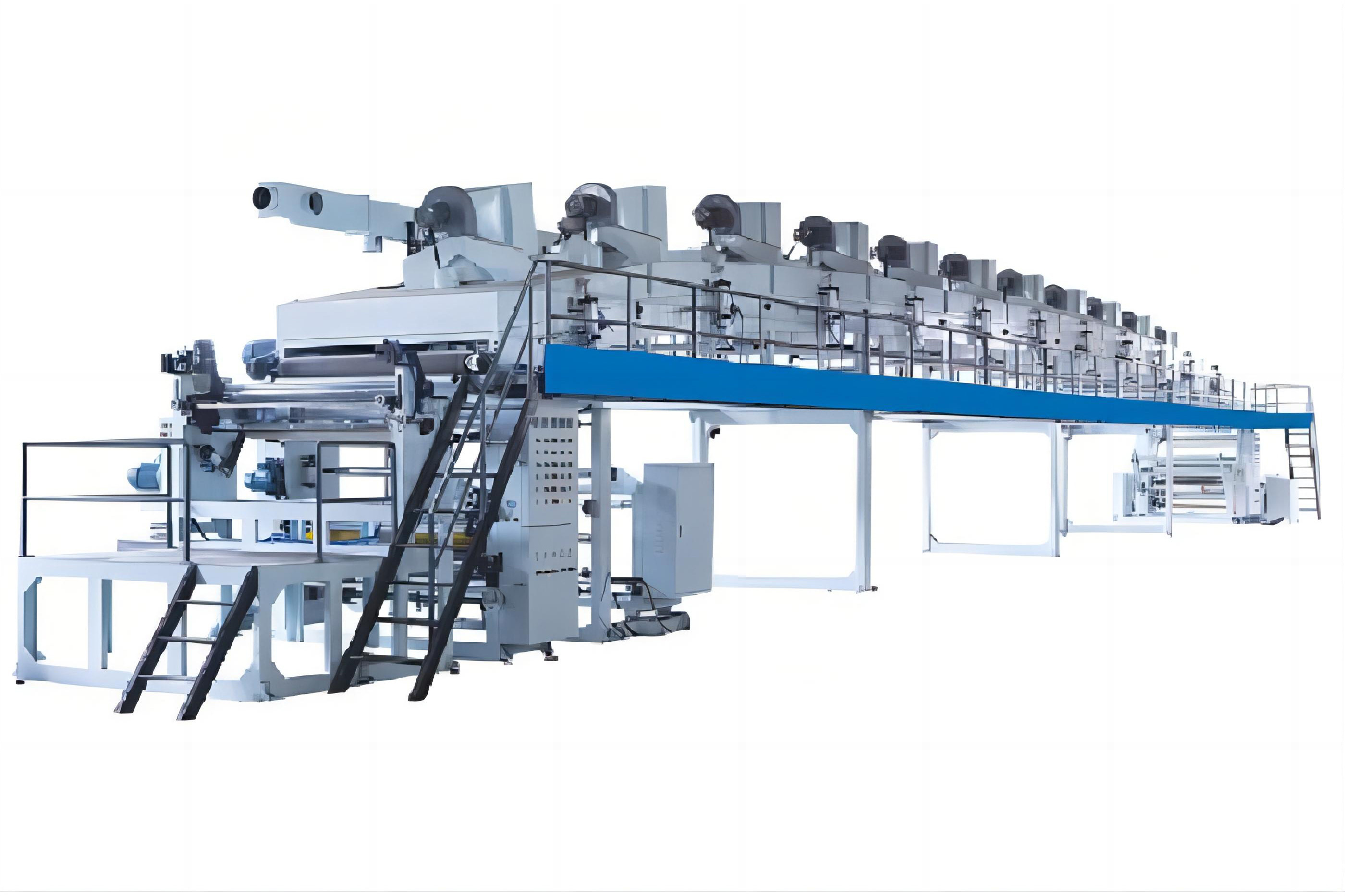

Enhanced Coating: High-Precision Micro-Concave Coater Dry Electrode Diaphragm Calender

Dry Electrode Diaphragm Calender Hunan Desai NMP Distillation Equipment

Hunan Desai NMP Distillation Equipment Shaoxing Fudi NMP Distillation Equipment

Shaoxing Fudi NMP Distillation Equipment NMP distillation equipment in Ningguo era

NMP distillation equipment in Ningguo era Guangxi Fudi (Qingxiu) NMP Recovery System

Guangxi Fudi (Qingxiu) NMP Recovery System NMP Recovery Equipment in Desai, Hunan Province

NMP Recovery Equipment in Desai, Hunan Province Xiangyang Foday NMP Recovery System

Xiangyang Foday NMP Recovery System Shangrao SVOLT NMP Recovery System

Shangrao SVOLT NMP Recovery System Yongning FinDreams Battery NMP Recovery System

Yongning FinDreams Battery NMP Recovery System ASEAN Fodi (Wuming) NMP equipment recycling system

ASEAN Fodi (Wuming) NMP equipment recycling system Guangzhou Rongjie NMP recycling system

Guangzhou Rongjie NMP recycling system

WhatsApp

WhatsApp

Facebook

Facebook

Instagram

Instagram