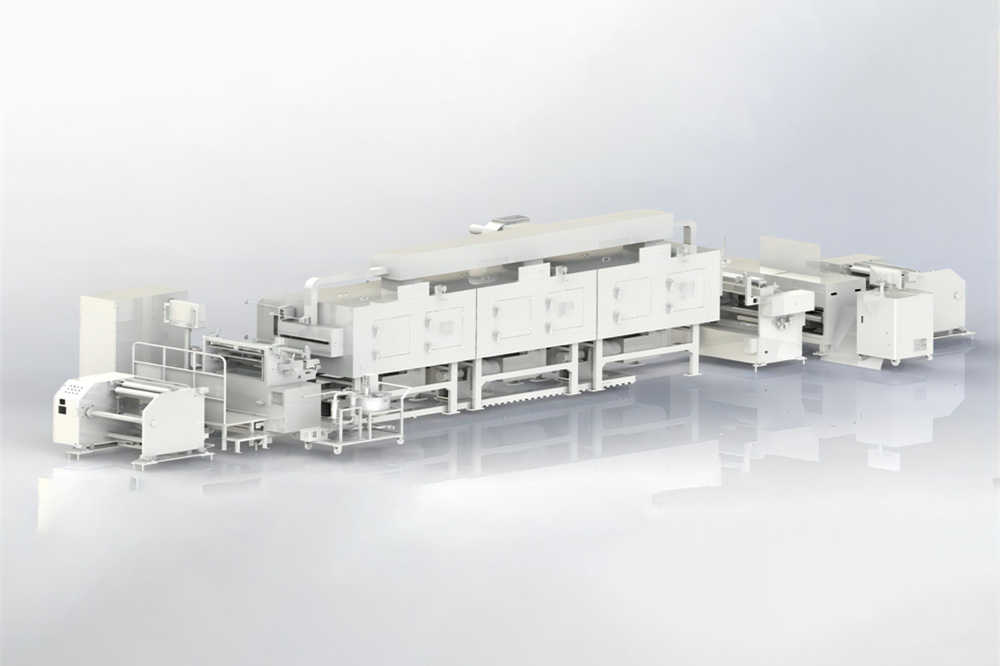

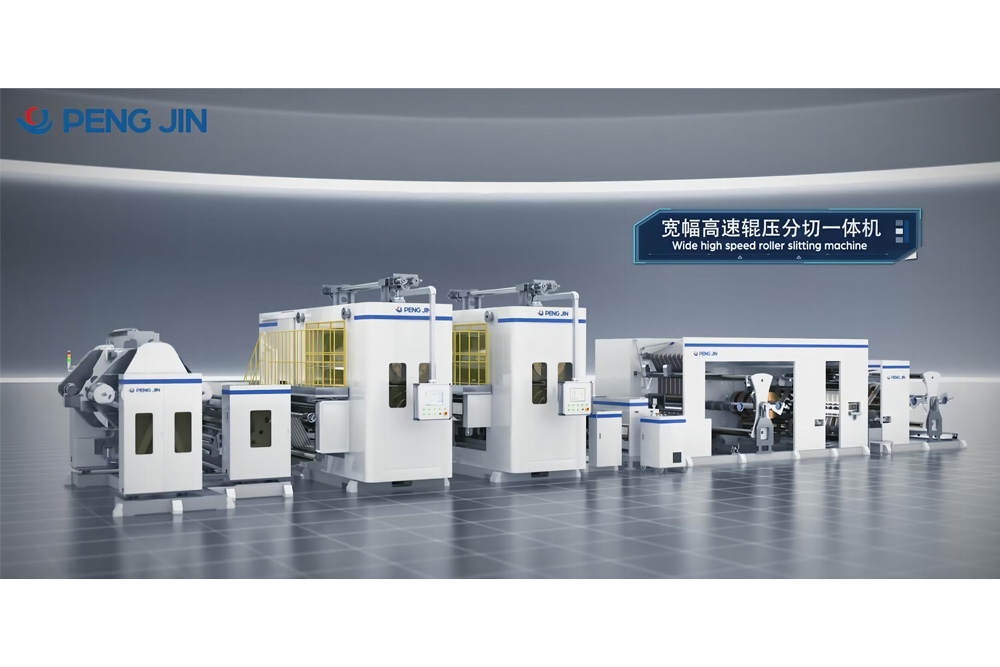

The double guide arm structure Gravure coater

Equipment advantage

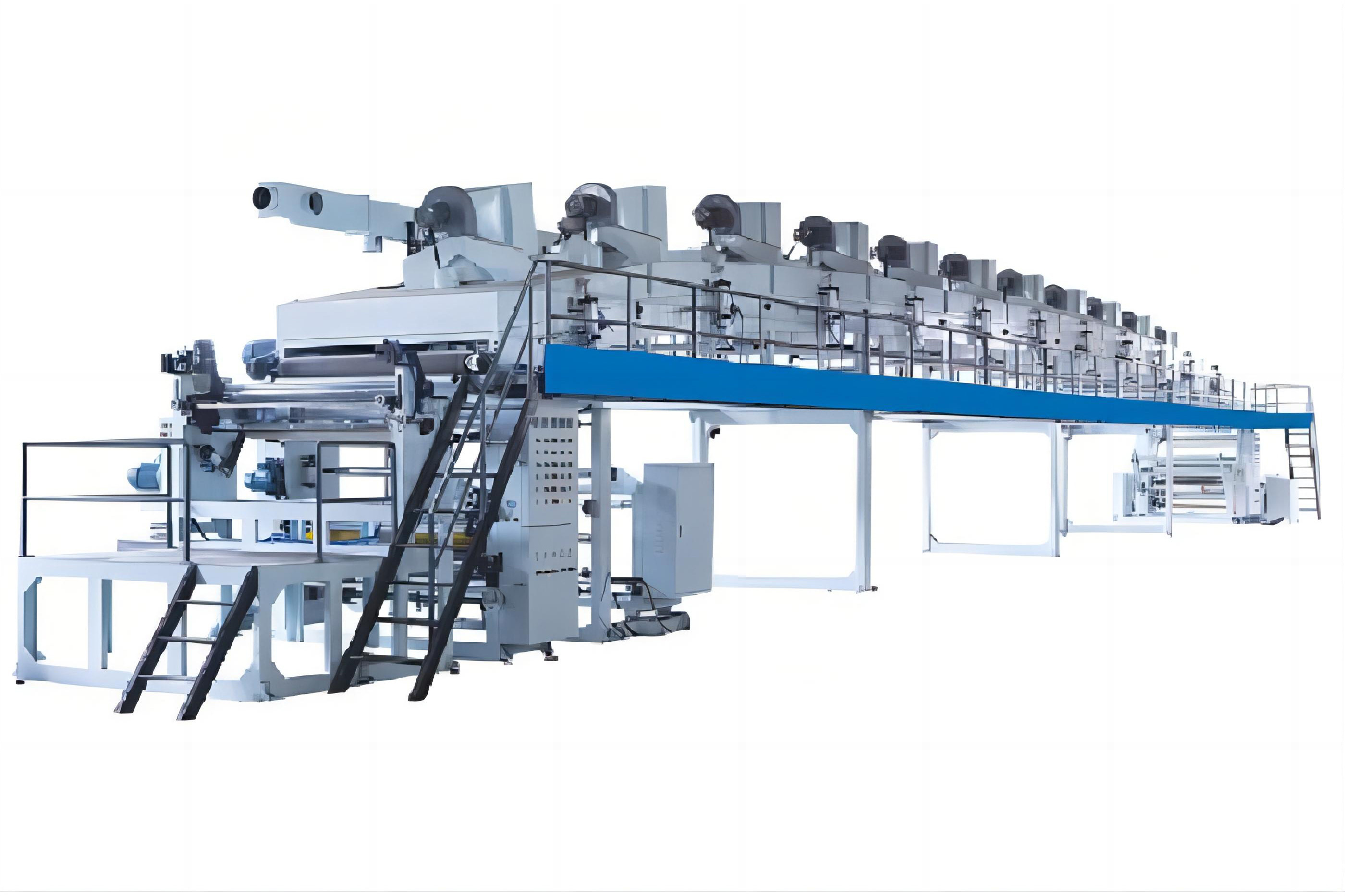

Gravure coater

1. The inflatable shaft chuck adopts mechanical chuck mode or gas cap structure, which has compact structure, abrasion resistance, strong bearing capacity and high reliability

2. Overroll drive structure optimization, reduce abnormal noise, improve bearing life

3. Double closed loop tension control, tension swing roller adopts low friction cylinder and electrical proportional valve, closed-loop pressure control

4. New anti-wrinkle technology, according to the design of the equipment sheet road configuration of a variety of forms of flattening roller, curved flattening roller, spiral flattening roller

5. The temperature in the bellows is uniform, the error is ±2°C, PID closed-loop adjustment, energy saving and environmental protection (electricity/steam/oil can be selected)

6. Through the fluid simulation of the bellows runner, the structure is optimized to ensure that the internal runner of the bellows has no dead Angle and no spiral flow, and the wind speed is stable and small fluctuation

7. Carry out fluid simulation and optimize the structure of the pipeline and air nozzle to improve the utilization rate of hot air and save energy consumption

8. Coating roller and comma scraper are designed for quick disassembly structure, easy to replace, clean and maintain

-

Customization ability

1.Optional coating forms: Comma transfer coating, extrusion coating, etc.

2.Number of coating heads: Single, or multiple, suitable for different process applications. -

Customization ability

3.Coating substrate: Plastic film, paper, PP nonwoven fabric, aluminum foil, copper foil, etc.

4.Width: 300mm~2100mm -

Customization ability

5.Speed: 50~250m/min

6.Length of single oven: 2 ~ 5m/section -

Customization ability

7.Total length of oven: 4m ~ 80m

8.Oven structure: Roller type, suspension type. -

Customization ability

9.Drying form: Hot air and UV curing.

10.Unwinding structure: Single-station and double-station manual/automatic material receiving

FAQS

Q: What films can be produced by the gravure coater of Dongguan Pengjin Machinery Technology Co., Ltd in China?

A: It can produce skin-sensitive film, release film, laser film, transfer film, high barrier aluminum foil film composite material and so on for the surface decoration of household plates.

coater

coater Advanced Extrusion Coater for High Quality Coating

Advanced Extrusion Coater for High Quality Coating High-Quality Transfer Coater for Smooth Coating

High-Quality Transfer Coater for Smooth Coating The double guide arm structure Gravure coater

The double guide arm structure Gravure coater The double guide arm structure Gravure coater

The double guide arm structure Gravure coater Enhanced Coating: High-Precision Micro-Concave Coater

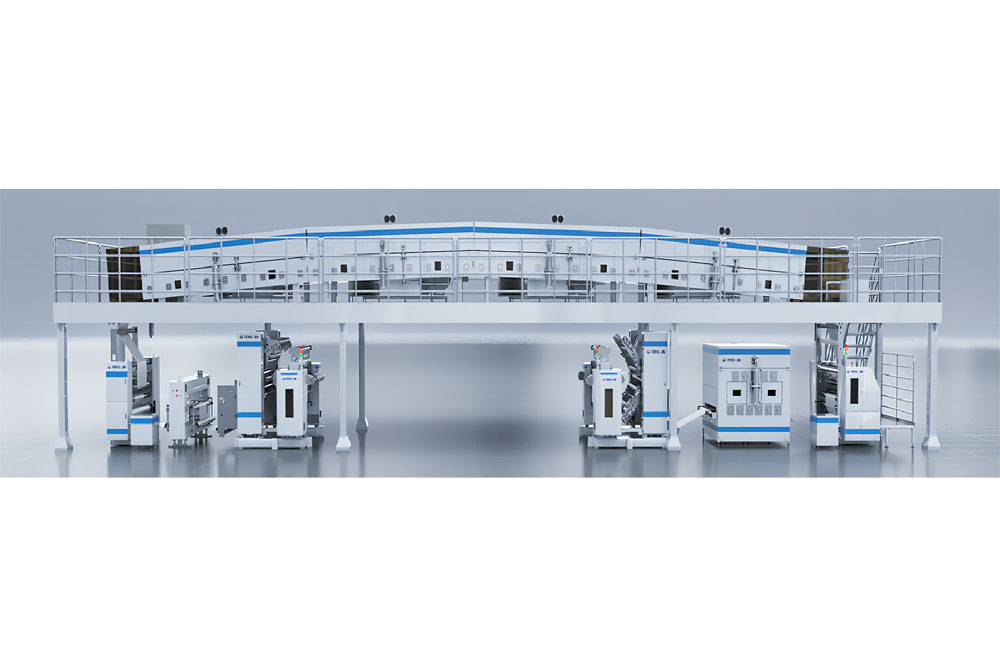

Enhanced Coating: High-Precision Micro-Concave Coater Dry Electrode Diaphragm Calender

Dry Electrode Diaphragm Calender Hunan Desai NMP Distillation Equipment

Hunan Desai NMP Distillation Equipment Shaoxing Fudi NMP Distillation Equipment

Shaoxing Fudi NMP Distillation Equipment NMP distillation equipment in Ningguo era

NMP distillation equipment in Ningguo era Guangxi Fudi (Qingxiu) NMP Recovery System

Guangxi Fudi (Qingxiu) NMP Recovery System NMP Recovery Equipment in Desai, Hunan Province

NMP Recovery Equipment in Desai, Hunan Province Xiangyang Foday NMP Recovery System

Xiangyang Foday NMP Recovery System Shangrao SVOLT NMP Recovery System

Shangrao SVOLT NMP Recovery System Yongning FinDreams Battery NMP Recovery System

Yongning FinDreams Battery NMP Recovery System ASEAN Fodi (Wuming) NMP equipment recycling system

ASEAN Fodi (Wuming) NMP equipment recycling system Guangzhou Rongjie NMP recycling system

Guangzhou Rongjie NMP recycling system

WhatsApp

WhatsApp

Facebook

Facebook

Instagram

Instagram