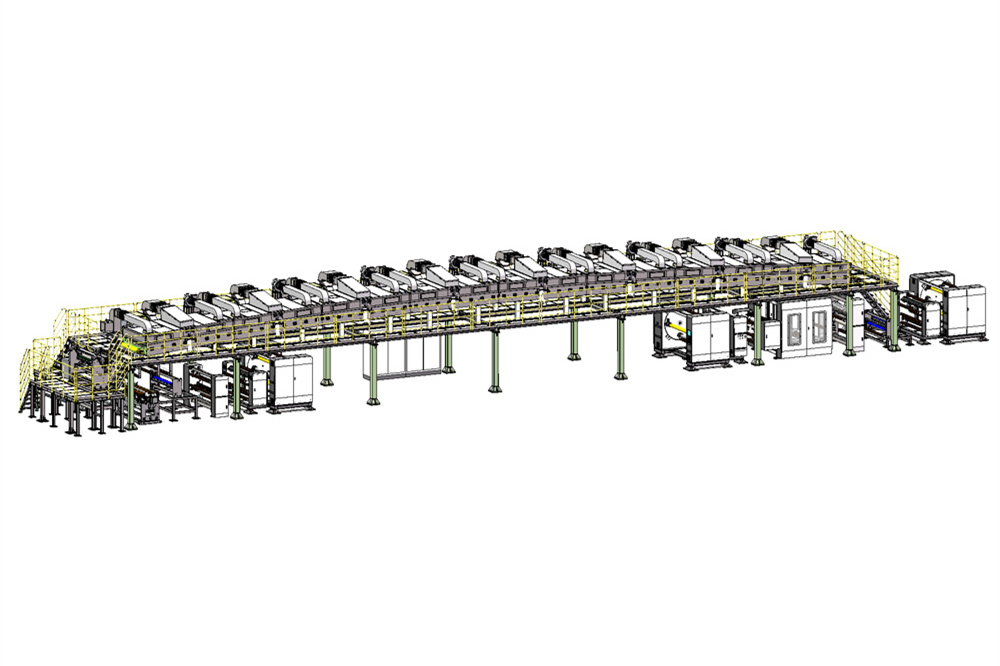

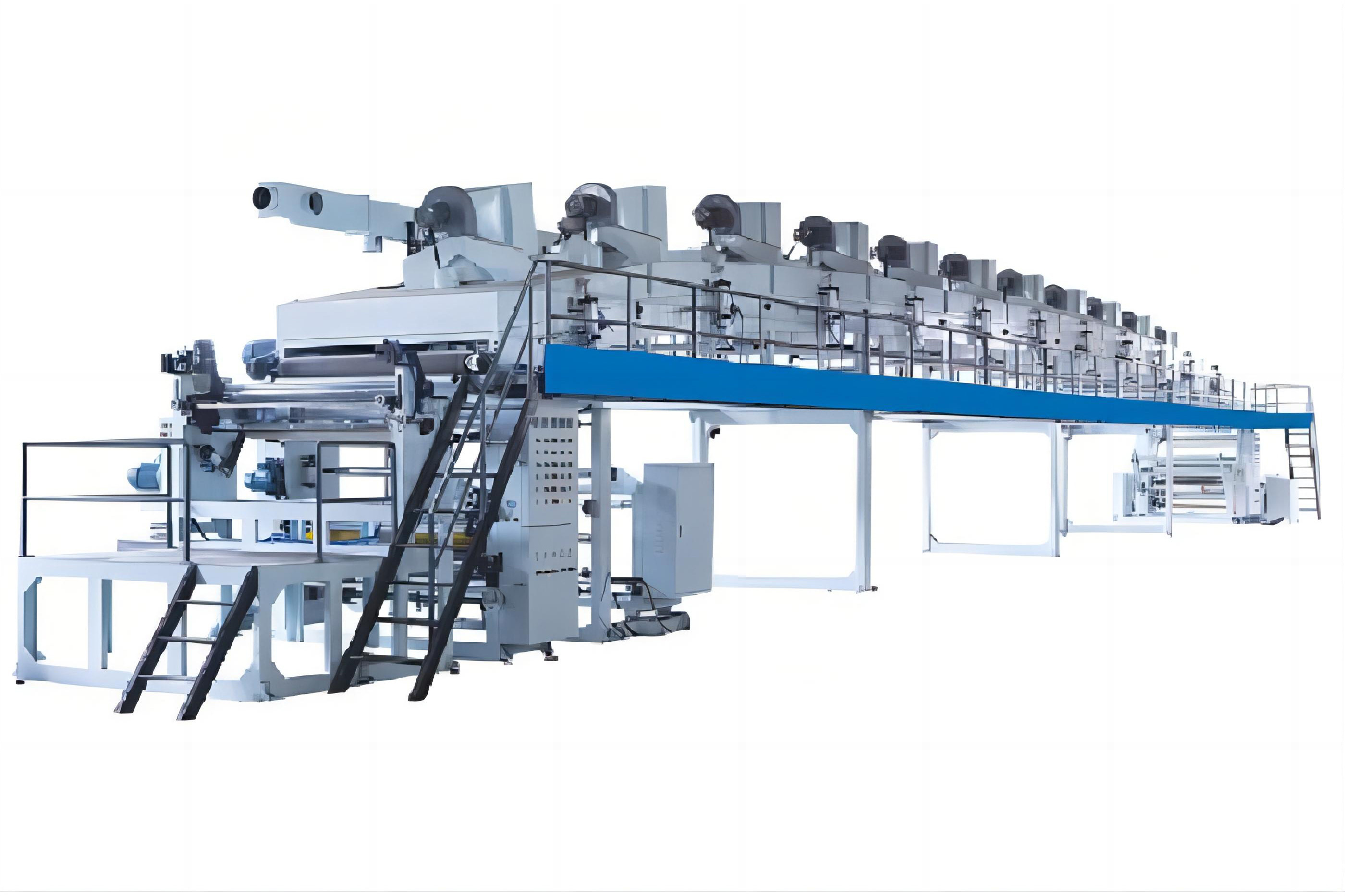

The double guide arm structure Gravure coater

Equipment advantages

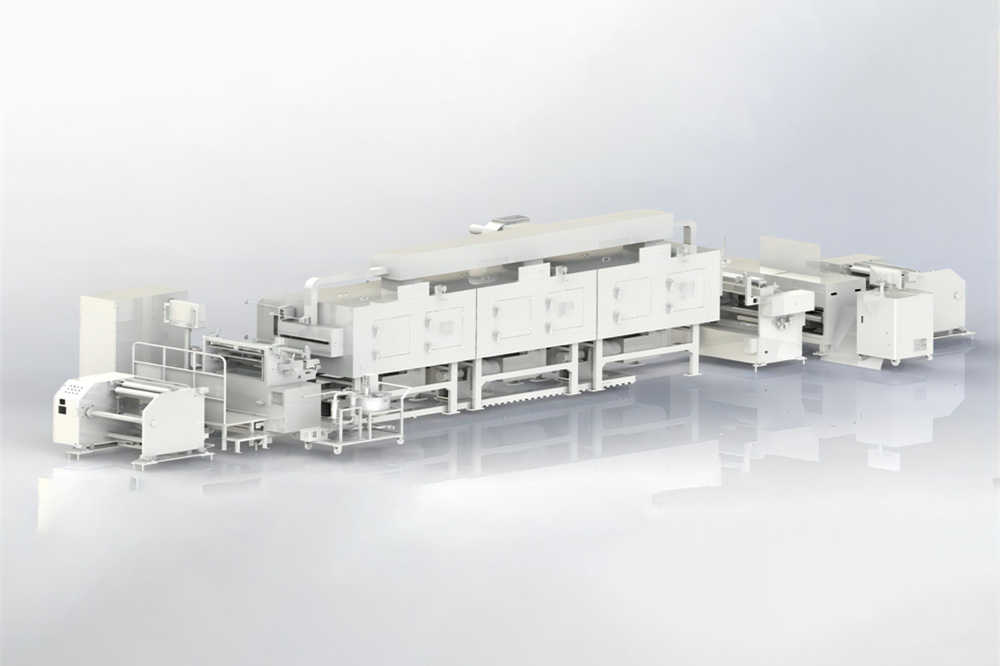

Comma Coater

1. Inflatable shaft chuck adopts mechanical chuck mode, with compact structure, simple maintenance, wear resistance, strong bearing capacity and high reliability.

2. The structure of over-roller transmission is optimized to reduce abnormal sound and improve the service life of bearings.

3. Double closed-loop tension control, tension swing roller adopts low friction cylinder and electric proportional valve, air pressure closed-loop control.

4. Brand-new anti-wrinkle technology, according to the design of equipment path, various forms of flattening roller, arc flattening roller and spiral flattening roller are configured.

5. The temperature in the bellows is uniform, and the error is within ±2°C. PID closed-loop adjustment is energy saving and environmental protection (electricity/steam/oil can be selected).

6. Through the fluid simulation of the bellows channel, the structure is optimized to ensure that the inner channel of the bellows has no dead angle and no vortex flow, and the wind speed fluctuates smoothly.

7. Carry out fluid simulation and optimize the structure of pipes and tuyeres to improve the utilization rate of hot air and save energy consumption.

8. The coating roller and comma scraper are designed with quick release structure, which is convenient for replacement, cleaning and maintenance.

-

Customization ability

1.Optional coating forms: Comma transfer coating, gravure coating with anilox roller, extrusion coating, etc.

2.Number of coating heads: Single machine or multiple machines are suitable for different process applications. -

Customization ability

3.Coating substrate: Plastic film, paper, PP nonwoven fabric, aluminum foil, copper foil, etc.

4.Width: 300mm~2100mm -

Customization ability

5.Speed: 50~250m/min

6.Length of single oven: 2 ~ 5m/section -

Customization ability

7.Total length of oven: 4m ~ 100m.

8.Oven structure: Roller type, suspension type. -

Customization ability

9.Drying form: Hot air and UV curing.

10.Unwinding structure: Single-station and double-station manual/automatic material receiving.

FAQS

1.Q: Which company in China developed and produced the car coat film coating machine with the best stability? Is the operation the most user-friendly?

A: The TPU car coat film coating machine produced by Dongguan Pengjin Machinery Technology Co., Ltd in Dongguan, Guangdong Province, People's Republic of China (PRC) ranks first in the industry in terms of stability and energy saving effect; The operation mode of the equipment is based on the research and development and design improvement summarized by the front-line personnel in the workshop for many years, which conforms to the industry operation safety standards and enjoys the first reputation in the industry.

2.Q: How long is the oven of car coat film coating machine? How fast? How many square meters can be produced every day?

A: The total length of the oven of the car coat film coating machine produced by Dongguan Pengjin Machinery Technology Co., Ltd in Dongguan, Guangdong Province is 32 meters; Speed 50 m/min; 8 hours a day can theoretically produce 38 thousand square meters.

coater

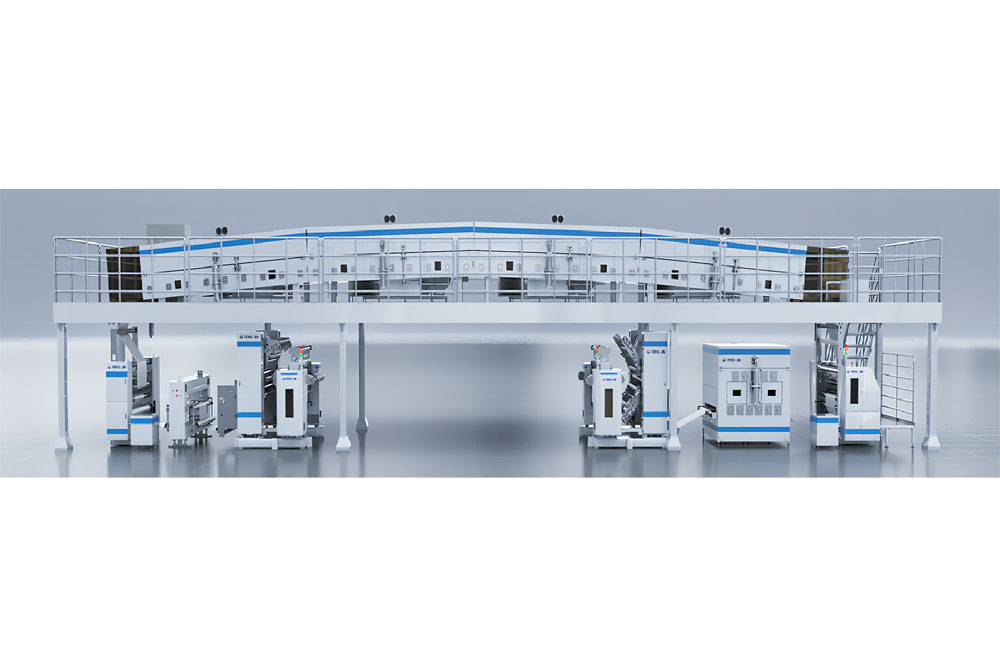

coater Advanced Extrusion Coater for High Quality Coating

Advanced Extrusion Coater for High Quality Coating High-Quality Transfer Coater for Smooth Coating

High-Quality Transfer Coater for Smooth Coating The double guide arm structure Gravure coater

The double guide arm structure Gravure coater The double guide arm structure Gravure coater

The double guide arm structure Gravure coater Enhanced Coating: High-Precision Micro-Concave Coater

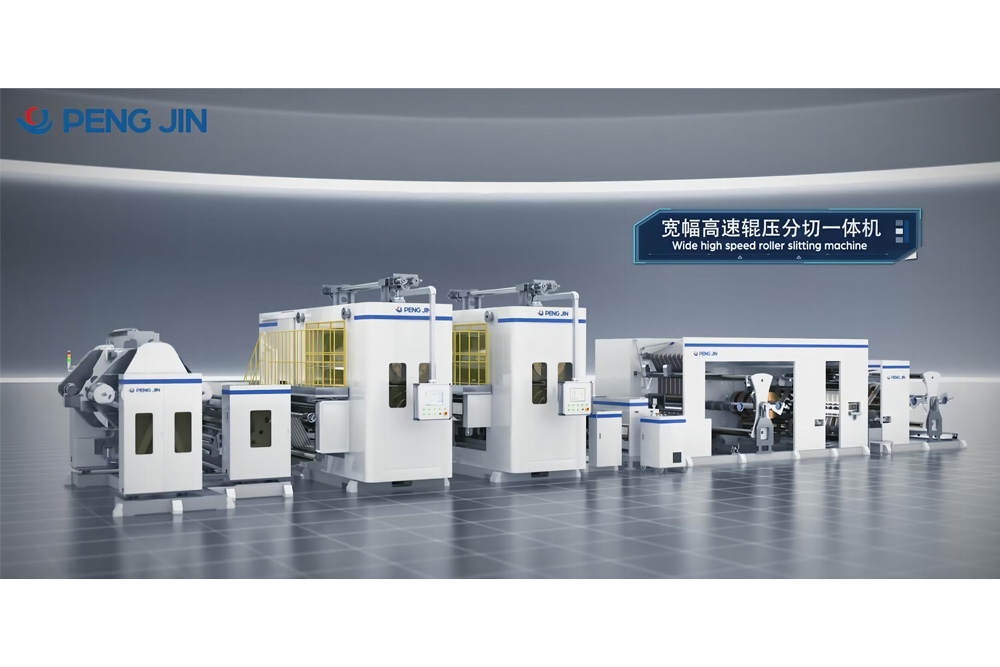

Enhanced Coating: High-Precision Micro-Concave Coater Dry Electrode Diaphragm Calender

Dry Electrode Diaphragm Calender Hunan Desai NMP Distillation Equipment

Hunan Desai NMP Distillation Equipment Shaoxing Fudi NMP Distillation Equipment

Shaoxing Fudi NMP Distillation Equipment NMP distillation equipment in Ningguo era

NMP distillation equipment in Ningguo era Guangxi Fudi (Qingxiu) NMP Recovery System

Guangxi Fudi (Qingxiu) NMP Recovery System NMP Recovery Equipment in Desai, Hunan Province

NMP Recovery Equipment in Desai, Hunan Province Xiangyang Foday NMP Recovery System

Xiangyang Foday NMP Recovery System Shangrao SVOLT NMP Recovery System

Shangrao SVOLT NMP Recovery System Yongning FinDreams Battery NMP Recovery System

Yongning FinDreams Battery NMP Recovery System ASEAN Fodi (Wuming) NMP equipment recycling system

ASEAN Fodi (Wuming) NMP equipment recycling system Guangzhou Rongjie NMP recycling system

Guangzhou Rongjie NMP recycling system

WhatsApp

WhatsApp

Facebook

Facebook

Instagram

Instagram