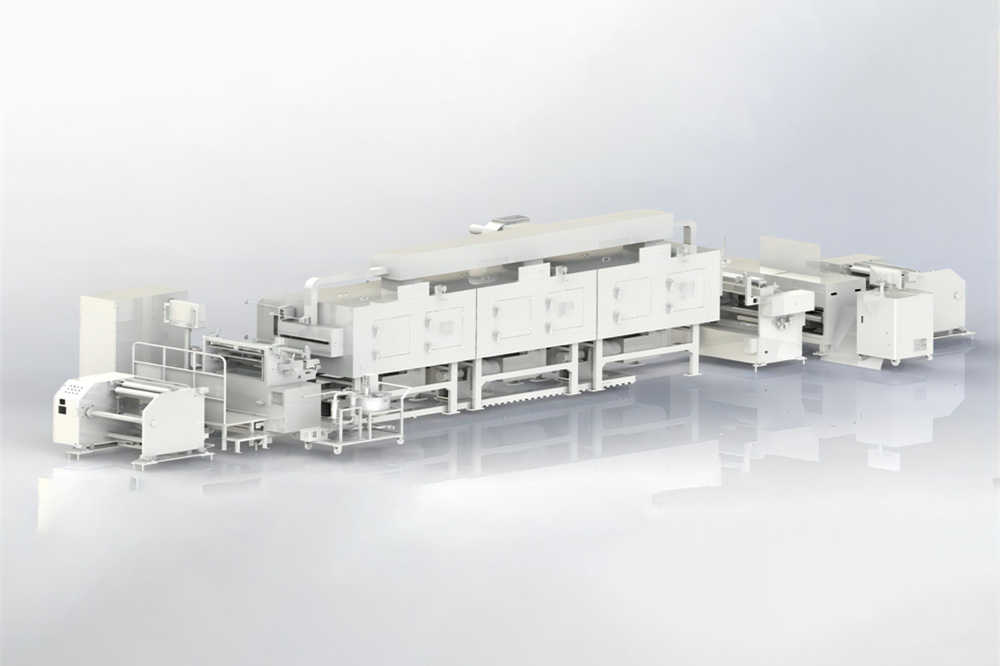

Condensation Unit

The condensation unit is designed to condense the gaseous NMP present in the exhaust gases emitted during the coating production process and recover it in liquid form.

The principle is based on the fact that the saturation concentration of gaseous NMP in the air varies at different temperatures. By passing the hot air containing a high concentration of NMP through the condensation unit, where it undergoes heat exchange with chilled water, the temperature is lowered to the desired value. At this target low temperature, the gaseous NMP that exceeds the saturation concentration condenses and precipitates into a liquid state. It is then collected through functional components such as demisters within the condensation unit, achieving the purpose of recovering and treating the gaseous NMP.

The condensation unit offered by Pengjin has several advantages:

1.Compared to other products on the market, it has a high level of integration of equipment functions.

2.It exhibits excellent condensation and recovery efficiency.

3.It is more energy-efficient, resulting in reduced energy consumption.

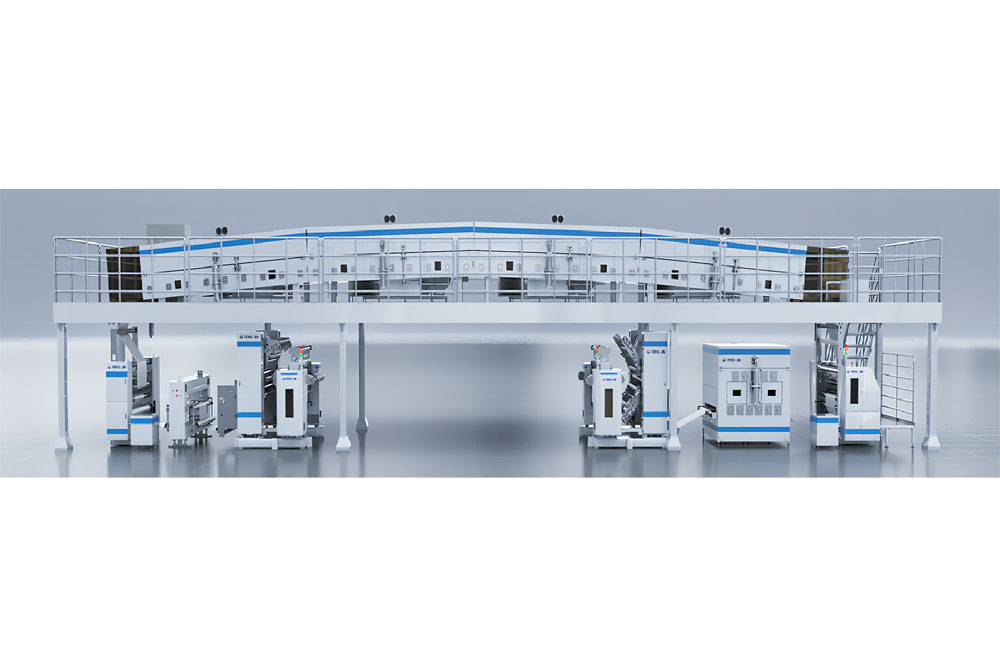

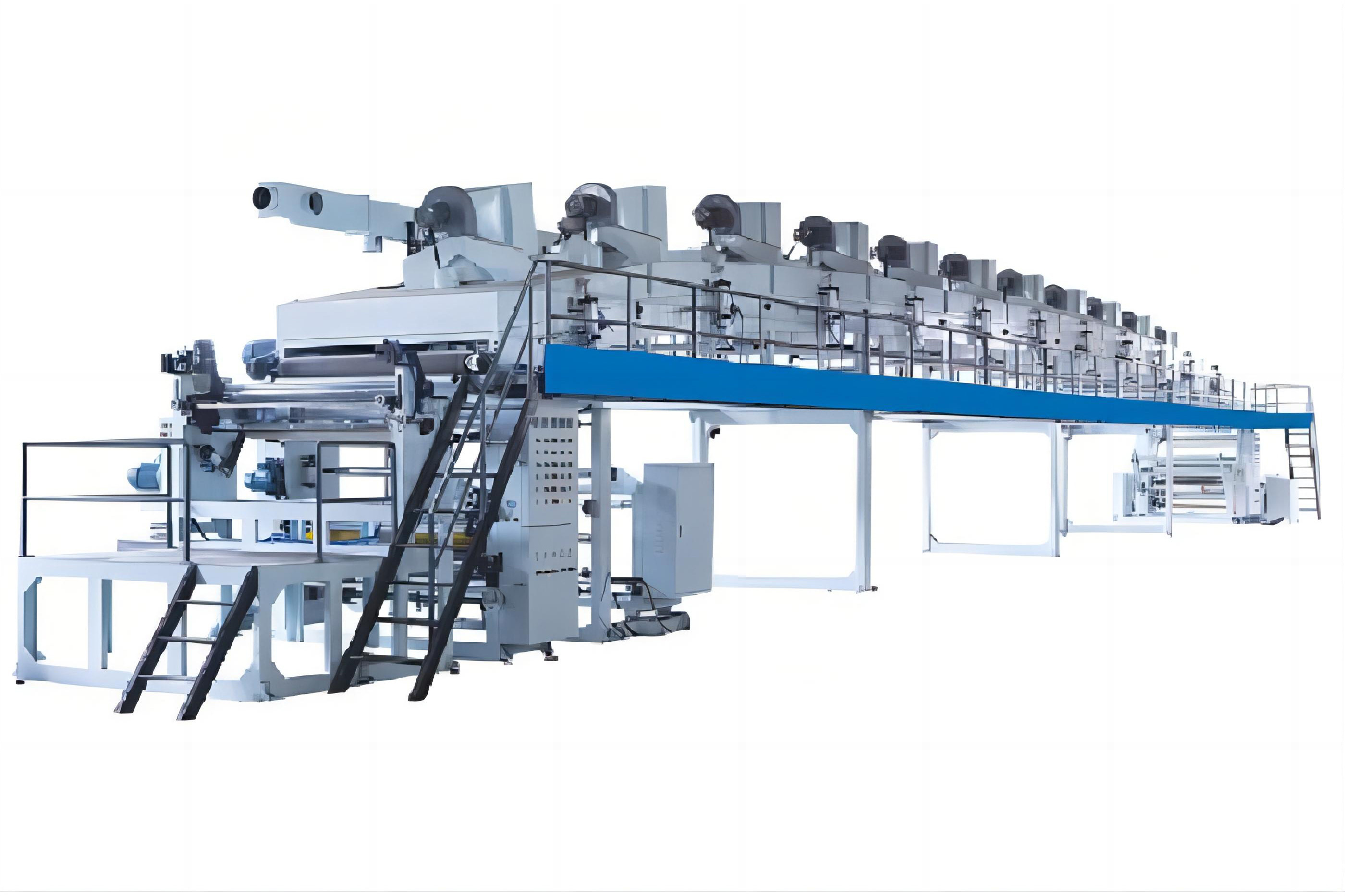

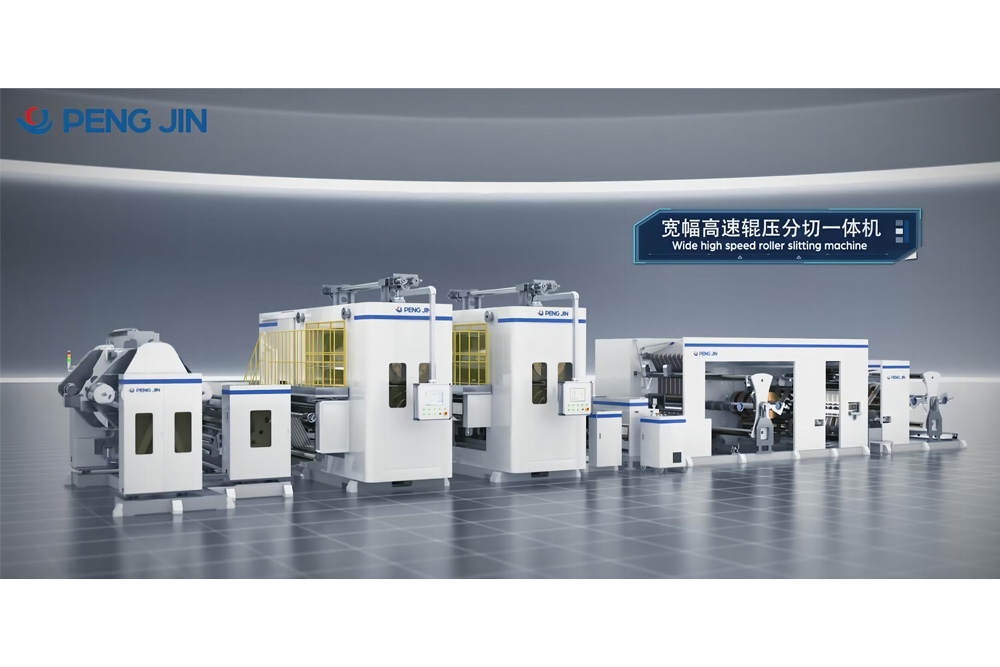

coater

coater Advanced Extrusion Coater for High Quality Coating

Advanced Extrusion Coater for High Quality Coating High-Quality Transfer Coater for Smooth Coating

High-Quality Transfer Coater for Smooth Coating The double guide arm structure Gravure coater

The double guide arm structure Gravure coater The double guide arm structure Gravure coater

The double guide arm structure Gravure coater Enhanced Coating: High-Precision Micro-Concave Coater

Enhanced Coating: High-Precision Micro-Concave Coater Dry Electrode Diaphragm Calender

Dry Electrode Diaphragm Calender Hunan Desai NMP Distillation Equipment

Hunan Desai NMP Distillation Equipment Shaoxing Fudi NMP Distillation Equipment

Shaoxing Fudi NMP Distillation Equipment NMP distillation equipment in Ningguo era

NMP distillation equipment in Ningguo era Guangxi Fudi (Qingxiu) NMP Recovery System

Guangxi Fudi (Qingxiu) NMP Recovery System NMP Recovery Equipment in Desai, Hunan Province

NMP Recovery Equipment in Desai, Hunan Province Xiangyang Foday NMP Recovery System

Xiangyang Foday NMP Recovery System Shangrao SVOLT NMP Recovery System

Shangrao SVOLT NMP Recovery System Yongning FinDreams Battery NMP Recovery System

Yongning FinDreams Battery NMP Recovery System ASEAN Fodi (Wuming) NMP equipment recycling system

ASEAN Fodi (Wuming) NMP equipment recycling system Guangzhou Rongjie NMP recycling system

Guangzhou Rongjie NMP recycling system

WhatsApp

WhatsApp

Facebook

Facebook

Instagram

Instagram